proudly serving

the mid-south

How to Reduce Commercial Ice Machine Downtime With Easy Maintenance Tips

When your commercial ice machine stops working, your whole business feels the strain. Whether you run a busy restaurant, a bar, or a healthcare facility in the Mid-South, downtime costs you time, money, and customer trust.

The best way to reduce ice machine downtime is to stay on top of regular maintenance and address small issues before they become big problems.

Cleaning your machine regularly, changing filters on schedule, and watching for common problems like mold or scale buildup keeps your ice clean and your equipment running smoothly. With the right care, you avoid costly repairs and keep your business cool year-round.

At Memphis Ice, we help Mid-South businesses stay prepared through expert service and reliable maintenance plans. You can count on us to handle your ice machine needs so you can focus on what matters most.

Understanding Commercial Ice Machine Downtime

Downtime with your commercial ice machine means lost ice, wasted time, and added costs. Knowing what causes these stops and spotting issues early keeps your business moving smoothly.

Common Causes of Downtime

Your ice machine can stop working for several reasons. The most common include clogged or dirty filters, worn-out parts, or problems with water supply.

Hard water can cause mineral buildup, which lowers ice quality and slows production. Failing to clean the machine’s interior regularly leads to bacteria growth and damaged components.

Electrical faults or control board failures can also cause downtime. Heavy-use machines need more frequent checks because parts wear out faster.

Getting on a regular maintenance schedule helps prevent most of these problems.

Impact on Business Operations

When your ice machine goes down, it can hurt your whole business. Restaurants may face slow service or unhappy customers.

Bars and hotels might run short on ice during busy times. Without ice, food safety can become a concern, especially if you rely on it for storage or display.

Unexpected repairs cost money and time. You could lose sales during downtime or pay extra to rent ice machines.

Your staff may have to work harder without a steady ice supply. These impacts add stress and disrupt smooth operations.

Identifying Early Warning Signs

Catching issues early can save you from big breakdowns. Pay attention to changes like slower ice production, unusual noises, or water leaks around the machine.

Ice that tastes off or looks cloudy is a sign that filters might need changing or the machine needs cleaning. Check for error codes if your machine has a digital display.

Regularly inspect external parts for wear or damage. Set a reminder for twice-yearly professional service to catch problems before they cause downtime.

Routine Maintenance Strategies

Keeping your commercial ice machine running means staying on top of daily tasks and planned upkeep. Focusing on regular cleaning, deep cleans, and routine inspections helps avoid breakdowns.

This makes sure your ice stays clean and your machine works without interruption.

Daily Cleaning Procedures

Start each day by wiping down the exterior and cleaning the ice bin. Use a soft cloth and mild detergent to remove dust, spills, and fingerprints.

This stops dirt from building up where it can cause issues. Empty leftover ice to prevent old ice from melting and refreezing, which can lead to poor quality.

Make sure the bin drain is clear so water flows freely. Sanitize your hands before handling the machine or ice.

This reduces germs and keeps your ice safe for customers. Following these simple daily steps lowers the chance of bacteria or mold growth.

Scheduled Deep Cleaning

Plan a deep clean every 1 to 3 months, depending on your environment and machine use. Turn off the machine and remove ice to access internal parts.

Use manufacturer-recommended cleaning solutions to scrub ice trays, water lines, and condenser coils. This removes mineral buildup, scale, and hidden mold.

Rinse thoroughly before restarting the machine to avoid chemical residue. Deep cleaning stops clogs, improves ice taste, and extends equipment life.

Create a cleaning calendar to keep track and stick to the schedule.

Inspection Checklists

Regular inspections catch small problems before they become big. Check these parts weekly:

- Water filters: Replace when dirty to protect water quality.

- Condenser coils: Clean dust and debris for proper cooling.

- Ice thickness: Ensure ice is forming evenly and at the right speed.

- Electrical connections: Look for loose wires or corrosion.

Use a simple checklist to document findings and note when repairs or replacements are needed. This helps avoid surprise breakdowns and keeps your ice machine ready for busy days.

Optimizing Usage and Operations

Using your ice machine the right way and keeping it in the best environment helps reduce downtime. Small changes in how you load it and where it runs can prevent damage and keep ice production steady.

Proper Machine Loading Practices

Avoid overfilling your ice bin. Too much ice puts extra strain on the machine’s components.

Keep ice levels within the recommended limits to maintain smooth operation. Empty the ice bin regularly.

Old ice can melt and refreeze, leading to clumps and blockages. This can slow down ice production and cause mechanical stress.

When loading the machine, use clean, uncontaminated water. Mineral buildup from hard water is a common cause of downtime.

If your water supply is hard, consider installing a water filter or softener. Check the ice bin and machine area for any trash or debris.

Foreign objects can damage moving parts or clog the drainage system, leading to costly repairs.

Optimal Operating Conditions

Place your commercial ice machine in a cool, well-ventilated area. Heat buildup reduces efficiency and can cause the compressor to overwork.

Maintain a stable room temperature between 50°F and 90°F. Extreme heat or cold stresses the refrigeration system.

Avoid direct sunlight or placing the machine near heat sources like ovens or fryers. This raises the workload and can lead to breakdowns.

Ensure your machine has at least 6 inches of clearance around all sides for airflow. Blocked vents lead to overheating, which is a leading cause of downtime.

Regularly monitor your machine’s settings. Using energy-saving modes reduces wear on parts and helps prolong your ice maker’s life.

Employee Training for Efficient Operation

Proper employee training helps your team run the ice machine smoothly and spot issues early. Teaching clear processes and careful habits reduces mistakes and keeps your machine working without costly delays.

Training Best Practices

Give your workers step-by-step instructions on how the ice machine works. Use simple guides and hands-on demonstrations.

Show them how to clean filters, check water supply, and recognize warning signs like unusual noises or leaks. Regular refresher sessions help keep everyone sharp.

Keep training short and focused, covering key points like daily checks and safe cleaning methods. Use checklists to track what’s done and avoid steps being missed.

Encourage questions so your team feels comfortable reporting problems early. Clear communication keeps small issues from turning into machine breakdowns.

Error Prevention Techniques

Teach your employees to watch for common mistakes that cause downtime. Not cleaning filters can block water flow and slow ice production.

Running the machine when water temperature is too high also stresses parts. Encourage routine inspections.

Spot things like worn seals or damaged hoses before they cause leaks. Remind staff to turn off the machine during cleaning or repairs to avoid electrical issues.

Using simple tracking tools like logs for maintenance and cleaning reinforces good habits. When everyone knows their role, your ice machine stays reliable and you avoid surprise repairs.

Monitoring and Remote Diagnostics

Keeping a close eye on your ice machine’s health helps catch problems early and avoid costly downtime. Modern tools help you track key data and get alerts before small issues become big repairs.

Using Smart Monitoring Tools

Smart monitoring tools connect your ice machine to the internet and watch how it’s running in real time. These tools check things like temperature, ice production speed, and water flow.

When something is off, you get an alert right away on your phone or computer. You can call for service fast and avoid ice shortages during busy times.

Some systems let technicians access your machine remotely. This saves time by diagnosing problems before they visit.

For businesses in Memphis and the surrounding Mid-South region, smart monitoring helps keep ice machines working smoothly year-round.

Tracking Performance Data

Tracking your machine’s performance data over time reveals patterns that matter. You can see if ice output is slowing down or if the machine uses more energy than usual.

These signs point to parts needing cleaning or replacement before a breakdown happens. Set a schedule to review this data weekly or monthly.

Keep records of water quality, filter changes, and cleaning dates too. This simple tracking helps you plan maintenance better.

Establishing Rapid Response Protocols

Quick action when your ice machine goes down helps cut downtime and keeps your business running smoothly. Having clear plans and assigned roles means issues get handled fast.

Creating Emergency Downtime Plans

Start with a written plan outlining what to do when your ice machine stops working. Include steps like checking power, inspecting water lines, and performing a quick reset if possible.

List contact info for your trusted service team and rental suppliers. Make sure everyone on your staff knows how to access this info.

Keep backup ice machine rentals ready if your main unit needs longer repairs. Having a plan reduces guesswork and speeds up recovery during busy times.

Assigning Response Roles

Give specific staff members clear responsibilities in case of an ice machine failure. One person checks the machine and tries simple fixes.

Another contacts your service provider, while someone else handles customer communication. Train your team so they know who does what.

When everyone understands their role, problems get solved faster without confusion. Using a simple checklist for each role helps keep tasks on track during the stress of a breakdown.

Working With Professional Service Partners

Having a trusted team on your side helps keep your ice machine running without costly stops. Reliable technicians and clear maintenance agreements work together to reduce downtime and protect your business.

Choosing Reliable Technicians

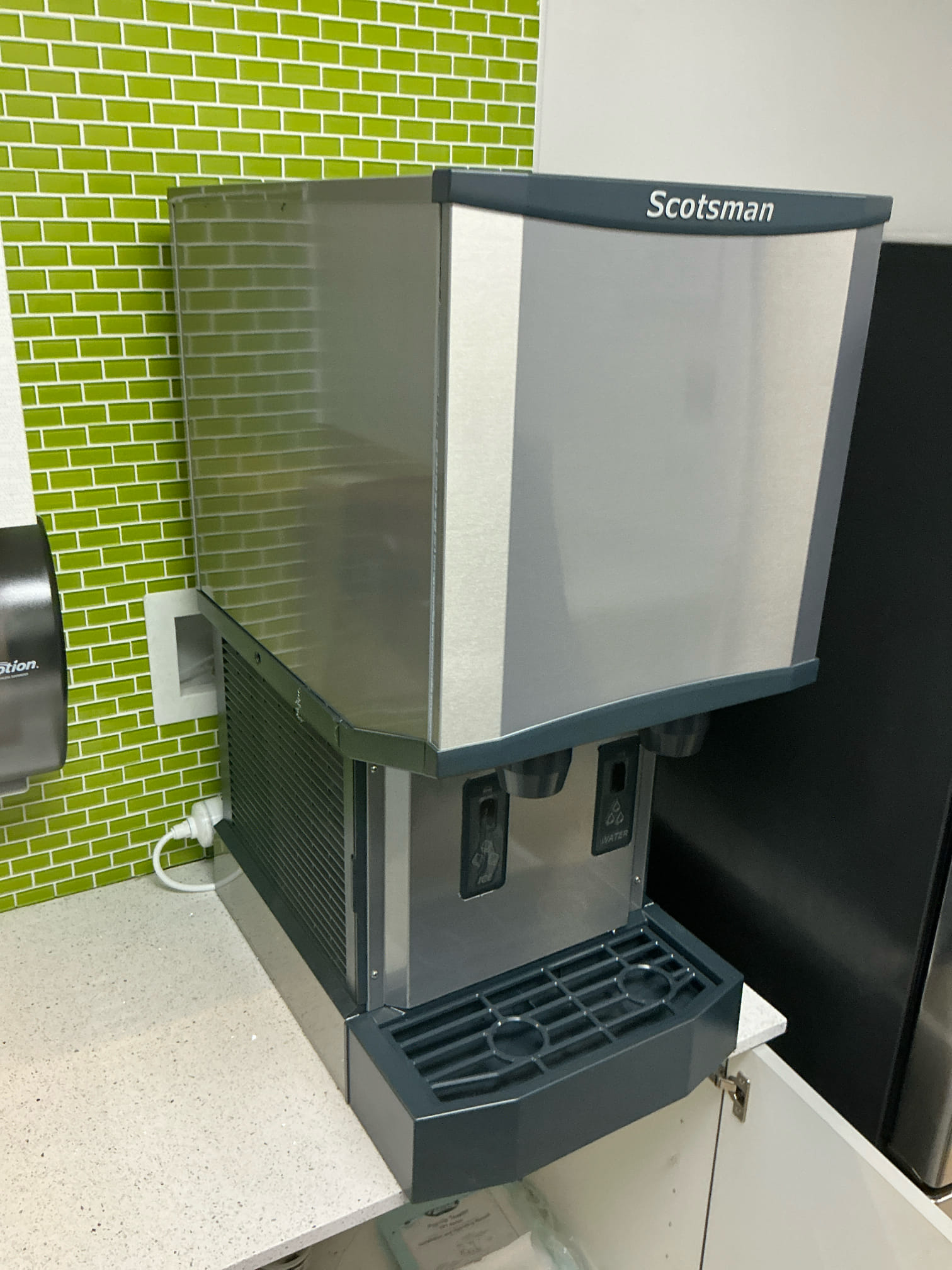

Pick technicians who understand commercial ice machines inside and out. Experience with your specific brand or model means they can spot problems early.

Look for a service partner with a strong local reputation, preferably with years of work in the Mid-South or Memphis area. Ask about certifications and how quickly they respond to service calls.

Fast, knowledgeable help means less downtime. Check if they offer preventive maintenance and emergency repairs.

A good technician helps you avoid issues with routine checkups, not just fix problems.

Setting Up Maintenance Agreements

A maintenance agreement sets regular service visits so you don’t have to remember everything on your own. These agreements keep your ice machine clean, running efficiently, and compliant with health codes.

Most agreements include scheduled cleanings, inspections, and minor repairs. Work with your service partner to customize your plan based on how often you use your machine.

If you run your ice maker nonstop, biannual or quarterly visits might be best. Clear communication about what’s included and response times guarantees you won’t be caught off guard.

Sourcing High-Quality Replacement Parts

Getting the right parts quickly helps keep your ice machine working without long stops. Knowing how to spot real parts and which spares to keep on hand reduces unexpected downtime and repair costs.

Identifying Genuine Parts

Using genuine parts helps your machine run as it should. Look for parts made by the original manufacturer that match your ice machine’s brand and model.

Check serial numbers and packaging to avoid fake or low-quality parts. These can cause damage and cost more in repairs.

Ask your trusted local provider if they stock authentic components. Reliable dealers usually guarantee their parts and offer expert advice to help you find what fits your machine.

Stocking Critical Spares

Keep a small supply of key parts on hand to speed up repairs. Important items include filters, water inlet valves, gaskets, and fan motors.

Having these ready means you don’t wait for shipping when your machine breaks down. It also helps maintain your ice quality and keeps service calls short.

Store spares in a clean, dry place. Check expiration or wear dates regularly to avoid using old or damaged parts.

Evaluating and Upgrading Old Ice Machines

You want your ice machine working without surprise breakdowns. Knowing when to replace an old unit and what newer models offer helps you avoid downtime and costly repairs.

Signs It’s Time to Upgrade

If your machine makes strange noises, produces less ice, or leaks water, it may be showing wear that regular fixes can’t solve.

Frequent breakdowns or repairs that cost more than half the price of a new machine mean an upgrade could save you money.

Older machines often use more electricity and water. Upgrading can improve efficiency and reduce utility bills.

If ice quality drops—cloudy or smelly ice—it may mean the machine’s parts or filters are too worn to fix easily.

Comparing Modern Options

New commercial ice machines offer better technology to cut down on cleaning and maintenance time.

Look for features like built-in filtration systems to improve ice taste and prevent scale buildup.

Energy-efficient models can use up to 30% less power. This helps if your location has high utility costs.

Some machines have easier access for cleaning. This means less downtime during your routine maintenance.

Choose a commercial-grade filter that matches your water hardness. This keeps ice fresh and extends machine life.

Pick a machine suited to your business volume. This avoids overworking smaller units or wasting energy with oversized machines.

Tracking and Reducing Downtime Over Time

Track when and why your ice machine stops working to catch patterns. Keeping clear records and reviewing them regularly helps prevent future problems.

Maintaining Downtime Logs

Log every downtime event with these details:

- Date and time when the machine stopped

- Cause of the issue (if known)

- Duration of the downtime

- Actions taken to fix it

- Parts replaced or repaired

Use a simple spreadsheet or notebook for this. Accurate records help you spot recurring issues like clogged filters or water supply problems.

Make sure everyone on your team knows how to update the log. This creates accountability and gives a full picture of your machine’s health.

Analyzing Trends for Continuous Improvement

Review your downtime logs monthly or quarterly. Look for common causes or peak times when the machine fails.

For example, you might find that slow ice production happens more after busy weekends.

Identify small fixes that can prevent bigger problems, such as:

- Scheduling filter changes before ice quality drops

- Checking water lines regularly to avoid clogs

- Planning maintenance during slow business hours

Use this data to create a maintenance plan tailored to your ice machine’s behavior.

Frequently Asked Questions

Keeping your commercial ice machine running smoothly means knowing how to care for it and when to act if something goes wrong. Understanding common problems, maintenance routines, and where to get help will keep your ice flowing.

What steps can be taken for regular maintenance to avoid ice machine breakdowns?

Regular cleaning stops bacteria and ice buildup. Check water filters and replace them when needed.

Schedule professional inspections twice a year to catch issues early. Keep ventilation clear and watch for proper water pressure.

What are the four most common issues faced with commercial ice machines?

Slow ice production often comes from dirty parts, poor ventilation, low water pressure, or ice buildup inside the machine. Other common problems include mechanical failures, water leaks, and clogged filters.

How can you troubleshoot a commercial ice machine effectively?

Start by turning off the machine and checking for visible ice blockage or leaks. Make sure the water supply is steady and filters are clean.

Look for unusual noises or error lights. If you can’t find a simple fix, contact a professional to avoid further damage.

Where can I find a reliable commercial ice machine repair service?

Look for local service providers with a strong reputation in the Mid-South, like Memphis Ice. Choose companies offering full-service support, from installation and rentals to maintenance and repairs.

A trusted partner will provide quick service and valuable maintenance advice.

What are the best practices for ensuring continuous production from ice machines?

Stick to a consistent cleaning schedule. Keep the area around your ice machine well-ventilated.

Monitor water quality and pressure. Avoid letting ice buildup or debris inside the machine.

Schedule regular professional service to keep everything running steady all year.

How can you increase the efficiency of an ice machine to prevent slow ice production?

Keep filters clean and replace them on time. Make sure the machine is in a cool, well-ventilated space to avoid overheating.

Remove any internal ice buildup. Clean any dirty parts regularly.

These steps help your machine produce ice quickly and reliably.

Recent News

Emergency Cold Storage Solutions for Events Made Easy and Reliable

Common Reasons Ice Machines Run Loud and How to Fix Them Easily

Common Ice Machine User Mistakes and How to Prevent Them for Smooth Operation

Tips for Improving Airflow Around Commercial Refrigeration Units to Boost Efficiency and Longevity

Tips for Organizing Multi-Zone Walk-In Coolers Made Easy and Efficient

Tips for Organizing Walk-In Coolers for Faster Kitchen Workflow and Efficiency