proudly serving

the mid-south

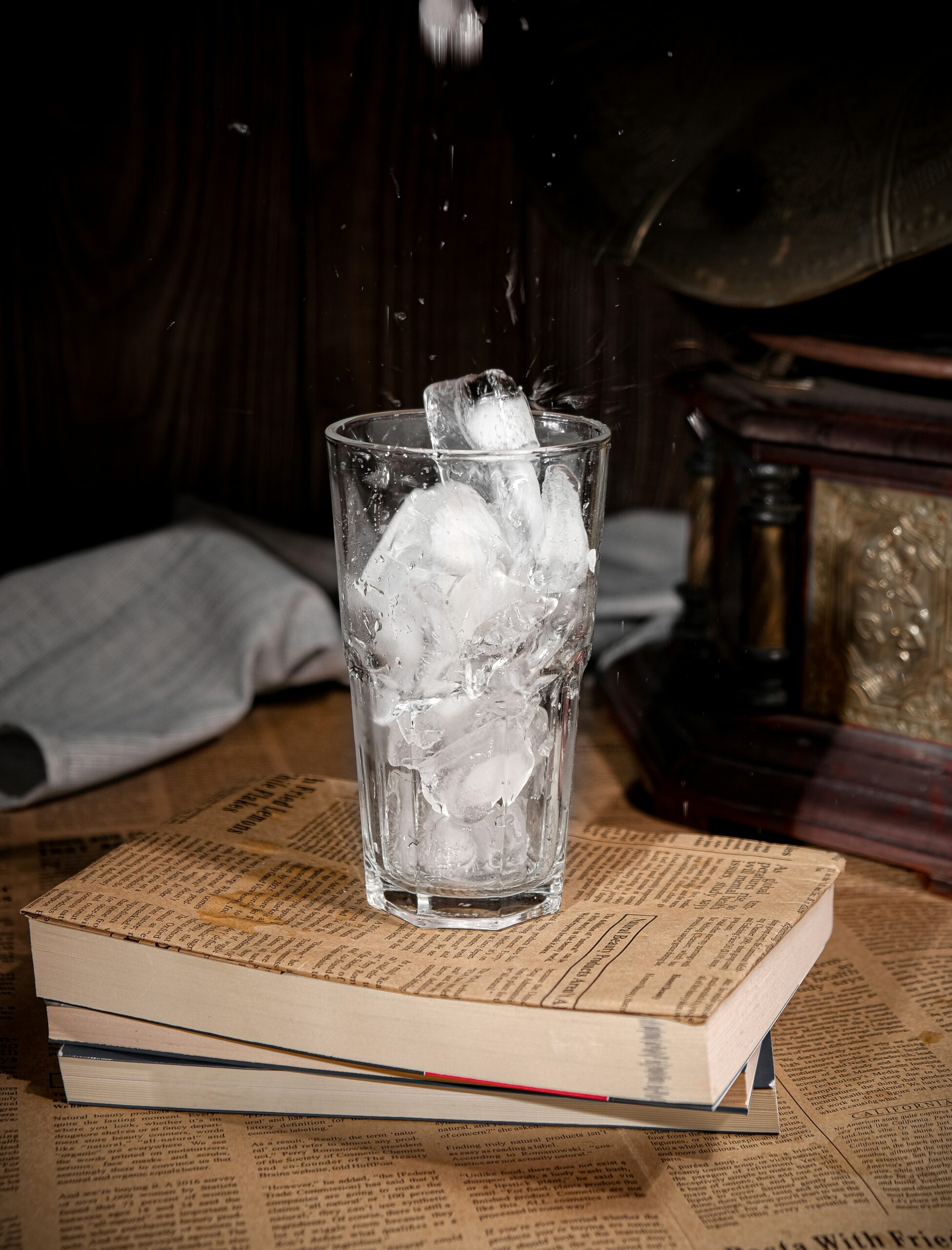

Cold Weather Doesn’t Mean Low Demand: How Ice Machines Perform in Winter

When temperatures drop, many business owners assume ice demand does too. In reality, winter presents a unique set of challenges for ice machines. They are challenges that often go unnoticed until performance starts to slip.

February is a critical month to understand how cold weather affects ice production and why winter maintenance matters just as much as summer prep.

Ice Is a Year-Round Essential

Restaurants, hospitals, convenience stores, hotels, and food-service operations rely on ice every day of the year. Iced beverages, food prep, chilled displays, and storage requirements don’t disappear when the weather turns cold. In many cases, winter events and indoor dining actually increase reliance on ice.

Just because it’s cold outside doesn’t mean your ice machine gets a break.

How Cold Weather Affects Ice Production

Winter impacts ice machines in subtle, but important, ways. Colder incoming water temperatures can slow freezing cycles, reducing overall production. Machines may appear to be functioning normally while quietly producing less ice per day.

Indoor environments also change in winter. Heating systems, tighter building airflow, and blocked vents can reduce efficiency. Machines tucked into storage rooms or kitchens may struggle with proper ventilation, causing compressors to work harder than necessary.

Hidden Problems Are Common in Winter

Because demand feels steady and machines aren’t visibly struggling, winter is when small issues often go unnoticed. Scale buildup, worn components, and drainage problems may not cause immediate failures, but they reduce output and increase the likelihood of breakdowns during peak demand.

By the time spring arrives, those small issues can turn into costly repairs.

Why February Maintenance Matters

February is one of the best months for preventive maintenance.

Cleaning removes mineral buildup that insulates freezing components and slows production. Inspections catch worn parts before they fail. Changing the filter improves water flow and ice clarity.

Regular winter service improves efficiency, reduces energy usage, and ensures consistent ice production long before patio season, catering, and events return.

Prepare for What’s Coming Next

Spring and summer bring higher traffic, outdoor seating, and increased drink volume. Businesses that wait until March or April to address ice issues often find themselves scrambling for service when schedules are already full.

Taking care of your ice machine in February puts you ahead of the curve.

Ice Doesn’t Take a Winter Break

At Memphis Ice Machine Company, we know ice is a year-round necessity. If your machine hasn’t been serviced recently, or you’re unsure how winter conditions may be affecting performance, give us a call: 901-235-3760. We’ll help ensure your ice production stays strong no matter the season.

Recent News

Planning Ahead: Why February Is Smart Timing for Ice Machine Upgrades or Rentals

Introducing Financing Through APPROVE: Flexible Payment Options Now Available

Love Is in the Ice: Why February Is the Perfect Time to Focus on Ice Quality

Tips for Energy-Efficient Use of Commercial Freezers to Save Money and Reduce Waste

Tips for Extending Lifespan of Walk-In Cooler Doors Friendly Maintenance and Care Guide

Tips for Extending the Life of Commercial Refrigeration Units with Easy Maintenance Habits