proudly serving

the mid-south

Best Practices for Cleaning and Sanitizing Commercial Ice Equipment to Keep It Safe and Sparkling

Keeping your commercial ice machine clean and sanitized is key to running a safe and efficient business. Regular cleaning stops germs and buildup, making sure your ice stays fresh and your equipment works well. You’ll dodge health risks and expensive repairs, so things keep humming along.

At Memphis Ice, we’ve been helping Mid-South businesses care for their ice machines since 1977. Whether you rent or own your unit, knowing the best cleaning practices will save you time and stress. Safe ice handling and proper maintenance also keep your customers happy and help you pass health inspections.

You don’t need to be a technician to keep your ice machine in decent shape. With clear steps and the right tools, anyone can follow good cleaning routines that protect your equipment and your health. Let’s dig into how to make ice machine cleaning simple—and not such a headache.

Understanding the Importance of Proper Ice Equipment Cleaning

Cleaning your commercial ice machine isn’t just about appearances. It’s about your customers’ health, your inspection results, and the quality of ice you serve. Why bother with thorough cleaning and sanitizing? Here’s what’s at stake.

Health and Safety Considerations

If you skip regular cleaning, ice machines quickly collect bacteria, mold, and slime. Not exactly the garnish you want in a drink. These nasties can make people sick when ice touches food, drinks, or even hands.

Cleaning knocks out mineral buildup and biofilms inside the machine. Sanitizing key spots like the bin, dispenser, and water lines stops germs from spreading.

And let’s be real—nobody wants ice that smells funky or tastes off. A clean machine means happy, healthy customers and staff, and you sidestep those avoidable health risks.

Regulatory Compliance

Health inspectors expect commercial ice machines to be cleaned and maintained properly. If you don’t keep your equipment sanitized, you could get fined or even shut down for a bit.

A lot of local codes require scheduled cleaning, sometimes every six months, sometimes even more often. Keeping records of cleaning and maintenance helps you prove compliance during inspections.

Meeting these standards means you avoid penalties, protect your license, and build trust with customers and inspectors.

Impact on Ice Quality

How your ice tastes and looks depends a ton on how clean your machine is. Minerals and grime can make ice cloudy and weird-tasting.

Gunk inside the equipment also slows down ice production and cranks up energy costs. Cleaning keeps things running smoothly and your ice up to par.

Regular maintenance just makes your machine last longer. When you keep parts free from deposits and clean those touchpoints, you prevent costly breakdowns and replacements.

Pre-Cleaning Preparation

Getting your commercial ice equipment ready for cleaning takes a bit of planning. You’ll want the right supplies, to power down the machine safely, and to know the steps ahead. This prep helps you avoid damaging anything and keeps your ice machine running right.

Gathering Necessary Cleaning Supplies

Before you dive in, grab all the cleaning materials you’ll need:

- Food-safe cleaning solutions made for ice machines

- Soft cloths or nonabrasive sponges

- Brushes for tight spots

- A bucket for rinsing

- Gloves to protect your hands

Use only products approved for your machine—no bleach or harsh acids unless the manufacturer says it’s fine. Keep everything nearby so you’re not running around mid-clean.

Shutting Down and Emptying Equipment

Always turn off your ice machine completely before cleaning. This stops water flow and ice-making, and keeps you safe.

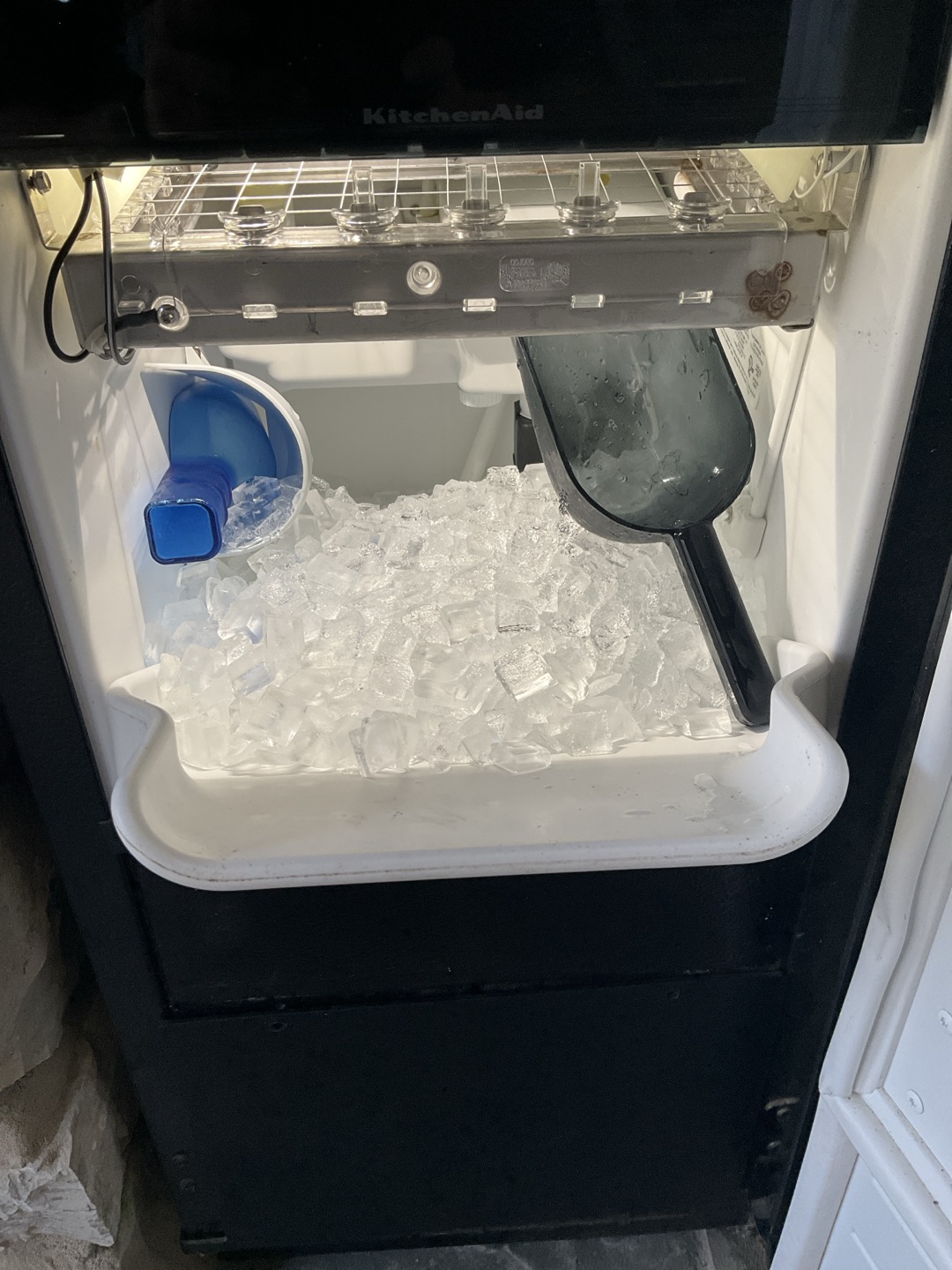

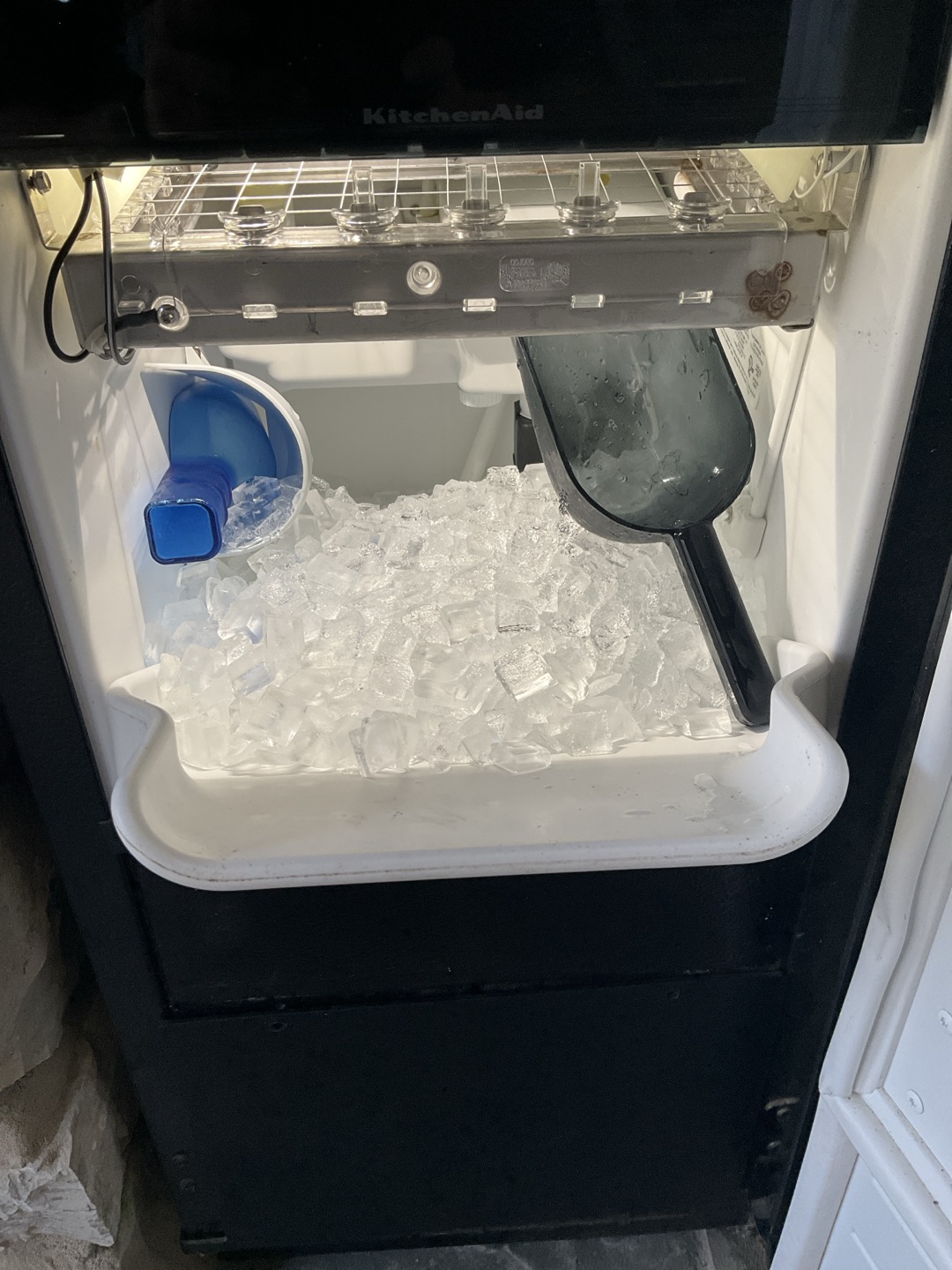

Next, scoop out all the ice in the bin. Get rid of any leftover cubes and water. Dry out the bin as much as you can. Leaving water or ice in there during cleaning just causes more gunk or could mess up parts.

Unplug the machine or shut off the breaker, just to be sure. If your machine has water shutoff valves, close those too.

Reviewing the Manufacturer’s Instructions

Every machine’s a little different. Your best bet? The manufacturer’s manual or cleaning guide. It’ll tell you:

- What cleaners are safe

- How often to clean and sanitize

- How to take apart parts safely

- Special care for filters or drains

Following these instructions keeps your warranty good and helps you avoid expensive mistakes. If you don’t have the manual, ask your supplier or hunt down a digital copy.

Routine Cleaning Procedures for Commercial Ice Machines

Keeping your ice machine clean means better-tasting ice and longer equipment life. Focus on daily wipe-downs, deeper cleaning of removable parts, and tackling mineral buildup inside the machine. These steps help your machine work right every day.

Daily and Weekly Cleaning Tasks

Each day, wipe down the machine’s exterior with a damp cloth to clear away dust and spills. Clean the ice storage bin to stop bacteria from setting up shop. Use warm soapy water, rinse well, and dry with a clean towel.

At least once a week, sanitize the ice chute and dispenser with a food-safe sanitizer. This stops germs from spreading every time someone dispenses ice. Keep an eye out for leaks, weird noises, or slow ice output—these might mean it’s time for a pro to take a look.

Jot down your cleaning times in a log. It’s not glamorous, but it helps you stick to a schedule and keeps things safe for everyone.

Cleaning Removable Ice Machine Parts

Take out and clean things like ice scoops, trays, and bin liners at least once a week. Wash these in warm water with mild detergent. Use a soft brush to scrub away slime and buildup in the harder-to-reach spots.

After cleaning, sanitize the pieces with a commercial sanitizer that’s safe for food surfaces. Let them air dry fully before putting them back. Skip harsh chemicals—they can wreck your parts or leave behind unsafe stuff.

Dirt and germs love to hide in corners, so get in there and clean thoroughly. If you’re unsure about removing parts, Memphis Ice can walk you through it.

Descaling the Interior

Minerals from water build up inside the ice machine and can mess with ice taste and quality. Descaling gets rid of this and keeps things running smoothly.

Use a commercial descaler made for ice machines. Follow the directions—usually you’ll drain the machine, add the solution, and run a cleaning cycle. Afterward, rinse everything well to get rid of any leftover residue.

Try to descale every 3 to 6 months, or sooner if you spot slow ice production or cloudy cubes. Regular descaling protects your machine’s guts and your customers’ health.

Deep Cleaning and Sanitizing Steps

Deep cleaning your commercial ice machine means scrubbing away buildup, killing germs, and making sure every part that touches water and ice is safe. You’ll want to use the right cleaners, sanitize the key internal parts, and dry everything properly. These steps keep your ice quality high and your equipment running longer.

Using Food-Safe Cleaners

Pick cleaners made for food equipment. These break down mineral deposits, slime, and gunk that can clog your machine or hide bacteria. Avoid harsh stuff that could damage parts or leave unsafe residues.

Follow the instructions on the label. Usually, you’ll mix the cleaner with water and apply it to all water and ice contact areas—think ice bin, evaporator, water reservoir. Let it sit as long as the label says.

Wear gloves to protect your skin. Use brushes or cloths to scrub into those tough spots. After cleaning, rinse everything well with clean water to clear away any leftover cleaner.

Sanitizing Water Lines and Reservoirs

Sanitizing is crucial for killing germs in the water lines and reservoirs. Use a food-grade sanitizer made for ice machines—this targets bacteria and mold that thrive in these damp, hidden spots.

Drain your machine, fill the reservoir or lines with sanitizer solution, and let it circulate or soak for the recommended time. Make sure every pipe and surface gets coated.

After sanitizing, flush everything with clean water. Any leftover sanitizer can taste bitter or even be unsafe. Regular sanitizing helps stop mold growth and keeps your ice clean between deep cleans.

Rinsing and Drying Components

Once cleaning and sanitizing are done, rinsing is vital. Use clean water to flush every part and get rid of chemicals and sanitizer. Double-check the nooks and crannies—residue can mess up ice or equipment.

Take out removable parts like bins and drip trays so they can air dry. Wipe down fixed surfaces with a clean cloth. Let the machine dry as much as possible before restarting to keep mold at bay.

Making rinsing and drying a habit will save you headaches and keep your ice tasting fresh.

Maintaining Storage Bins and Ice Dispensers

Keeping your ice storage bins and dispensers clean is huge for serving safe, fresh ice. Focus on getting rid of bacteria, mold, and slime that like to build up. This keeps your equipment working and avoids health issues.

Sanitizing Ice Bins

Remove the bin and any trays if you can. Clean these separately to make sure every surface that touches ice gets sanitized. Use a food-safe sanitizer made for ice machines and follow the label for how long to leave it on.

Don’t forget corners and the chute area—they’re easy to miss. After sanitizing, rinse everything well with clean water. Let the bin air dry or use a clean towel. Doing this regularly helps prevent slime and mold.

Cleaning Ice Scoops and Utensils

Ice scoops and other tools need daily attention. They touch ice directly and can carry germs if you skip cleaning. Wash them with hot, soapy water, then rinse well.

After washing, sanitize the scoops with the same food-safe sanitizer you use for bins. Store scoops in a clean, dry spot—not in the ice. Don’t use bare hands to handle ice if you can help it.

Following these steps helps keep your ice operation clean, safe, and reliable. At Memphis Ice, we know thorough maintenance is what keeps your ice fresh for your customers.

Facilitating a Cleaning Schedule

Keeping your commercial ice machine in shape means building a cleaning routine you’ll actually follow. Decide how often to clean, and keep track of what you’ve done. Both help you avoid breakdowns, keep ice safe, and extend your equipment’s life.

Establishing Cleaning Frequency

How often you clean depends on how hard your ice machine works. If it’s running all day, you might need to clean every two weeks. For quieter spots, maybe monthly is fine.

Watch for weird smells, slow ice, or leaks—those are signs to clean sooner. Set regular cleanings to stay ahead of problems.

Use a food-safe sanitizer every time. Many businesses stick to a daily, weekly, and monthly schedule for cleaning and deeper sanitizing. Adjust as needed for your usage and environment.

Creating a Maintenance Log

A maintenance log is the easiest way to track cleaning and repairs. Write down each cleaning date, what you did, and who did it. This keeps you from missing anything important.

It also helps you spot recurring problems or when your machine needs extra attention. Keeping records can come in handy during health inspections too.

You can use a paper log or a digital tool—whatever fits your style. Just update it right after each cleaning or service. At Memphis Ice, we always recommend this as part of regular care to keep things running without surprises.

Employee Training and Best Practices

Teaching your team how to handle ice machines safely and spot problems early keeps your equipment running and your ice clean. Clear guidance and regular updates help everyone stay on track.

Proper Handling and Safety Measures

Always have your team wash their hands before working with the ice machine. Gloves make a difference when touching ice or anything that touches ice—no one wants germs in their drink.

Show staff how to use the machine without forcing parts or ignoring warning signs. Cleaning or fixing the unit while it’s plugged in? Just don’t. Unplug first. Safe handling means fewer injuries and less damage.

Keep the area around the ice machine dry and free of clutter. Slippery floors from spilled water or ice are an accident waiting to happen. Clean the air vents regularly too—machines hate overheating.

Identifying and Addressing Common Issues

Train employees to notice slow ice production, weird smells, or odd noises. These clues usually mean the machine needs cleaning or repair. If you ignore them, you’re asking for trouble.

Use a cleaning checklist that covers all the machine’s important parts. Regular cleaning keeps mold and bacteria at bay. Food-safe sanitizers or a vinegar solution work well on the dispenser chute and inside surfaces.

If problems keep popping up, call a professional like Memphis Ice. Quick attention saves you from downtime and expensive repairs later.

Troubleshooting and Preventing Contamination

Keeping your commercial ice machine clean and safe isn’t rocket science, but you do need to spot problems early and keep contamination away. Mold or slime buildup? Yeah, that’s a red flag. Germs can sneak in from other surfaces if you’re not careful.

Recognizing Signs of Mold or Slime

Mold and slime love places where moisture and dirt meet—inside your ice machine or dispenser chute, for example. You might see a slimy film or weird patches of black, green, or white on the ice bin, water reservoir, or dispenser.

If ice tastes funny or smells odd, mold could be the culprit. Check inside the machine often, especially corners, drain lines, and under removable parts where water hangs out.

Scrubbing away mold early stops it from spreading to your ice cubes and corroding machine parts. Use the right cleaner and sanitizer for spots that look slimy or moldy. Regular cleanings really do help you stay ahead of the mess.

Preventing Cross-Contamination

Cross-contamination happens when germs jump from one surface to your ice or equipment. Always wash your hands before you handle ice or clean the machine. Use different cloths for the ice machine and other kitchen jobs—don’t mix them up.

Keep the ice scoop outside the bin and wash it often. Don’t let it touch the floor or anything dirty.

Make sure the ice bin lid fits tight to keep out dust and pests. Wipe down the dispenser chute every day—germs love to hide where ice drops out.

These habits lower your risk of bacteria or viruses getting into the ice. Customers trust you more when you keep things clean. If you’re not sure where to start with a cleaning plan, Memphis Ice can help.

Choosing Cleaning Products and Tools

Choosing the right cleaning products and tools keeps your commercial ice machine in shape and your ice safe. You want stuff that works, doesn’t wreck your equipment, and isn’t terrible for the planet. It also needs to be practical for a busy business.

Eco-Friendly and Non-Toxic Options

Eco-friendly, non-toxic cleaners protect your ice machine, your team, and your customers. Look for labels that say they’re safe for food contact. These products should kill mold, bacteria, and slime without tough chemicals that can eat away at machine parts.

Aim for biodegradable ingredients and no harsh fumes. They’re better for workers and don’t leave chemical gunk inside the machine. Your ice will taste better, and you’ll breathe easier. Lots of local suppliers and Memphis Ice carry green cleaning options made just for commercial ice machines.

Sourcing Supplies for Commercial Settings

For commercial use, go for durability, safety, and compliance. Grab soft scrub brushes, microfiber cloths, and food-grade sanitizers that meet health codes. Skip anything abrasive—scratches and damaged seals are a pain.

Buy from suppliers who know commercial kitchens or refrigeration. Stock up on replacement filters, sanitizing wipes, and pasteurizing chemicals that fit your machine. Memphis Ice can help you pick the right stuff so you’re not left scrambling. Keeping these supplies close makes routine maintenance a lot less of a headache.

Frequently Asked Questions

Cleaning and sanitizing your commercial ice equipment takes regular effort, the right products, and a little know-how. Health guidelines keep your ice safe, and avoiding common mistakes helps your machine last longer.

How often should commercial ice machines be cleaned and sanitized?

Clean and sanitize your ice machine every 1 to 3 months, depending on how much you use it. If you’re running it hard, go for monthly. Routine cleaning keeps things efficient and your ice safe.

What are some FDA guidelines for maintaining commercial ice equipment?

The FDA says you need to clean ice machines regularly to stop contamination. Ice that comes in contact with scoops or hands should stay away from germs. Sanitizing all removable parts and surfaces is important for health standards.

Can you recommend any commercial ice machine cleaning services?

Memphis Ice offers professional cleaning and maintenance for commercial ice machines. They take care of every step to keep your equipment clean and running smoothly. Regular service helps you dodge costly repairs and downtime.

What are the common mistakes to avoid while cleaning an ice machine?

Don’t forget to turn off the power before cleaning. Avoid harsh chemicals that can damage parts. Clean the dispenser chute and removable parts well. And always rinse off cleaning products completely.

What is the proper method to clean a Hoshizaki ice machine?

Turn off the machine and empty all the ice. Take out the ice bin and wash it with warm soapy water. Use a recommended ice machine cleaner inside, following the manufacturer’s instructions. Rinse and sanitize every part before putting it all back together.

What are the best sanitizers to use on Manitowoc ice machines?

Go for sanitizers that are safe for food contact—stuff like quaternary ammonium compounds or iodine usually does the trick. Just make sure you check the label and stick to Manitowoc’s own recommendations. The right sanitizer knocks out bacteria but won’t mess up the machine’s parts.

Recent News

Best Practices for Storing Food Around Ice Bins Safely and Efficiently

Best Practices for Loading and Unloading Walk-In Freezers Made Easy and Efficient

Best Practices for Cleaning Walk-In Cooler Shelving Tips for Maintaining Hygiene and Efficiency

Best Maintenance Tips for Bar Refrigeration Systems to Keep Your Drinks Cold and Equipment Running Smoothly

Benefits of Working with Certified Refrigeration Technicians for Reliable and Efficient Cooling Solutions

Walk-In Freezer Organization Tips for a Cleaner, More Efficient Space