proudly serving

the mid-south

Benefits of Ice Machine Maintenance Plans for Longevity and Efficiency

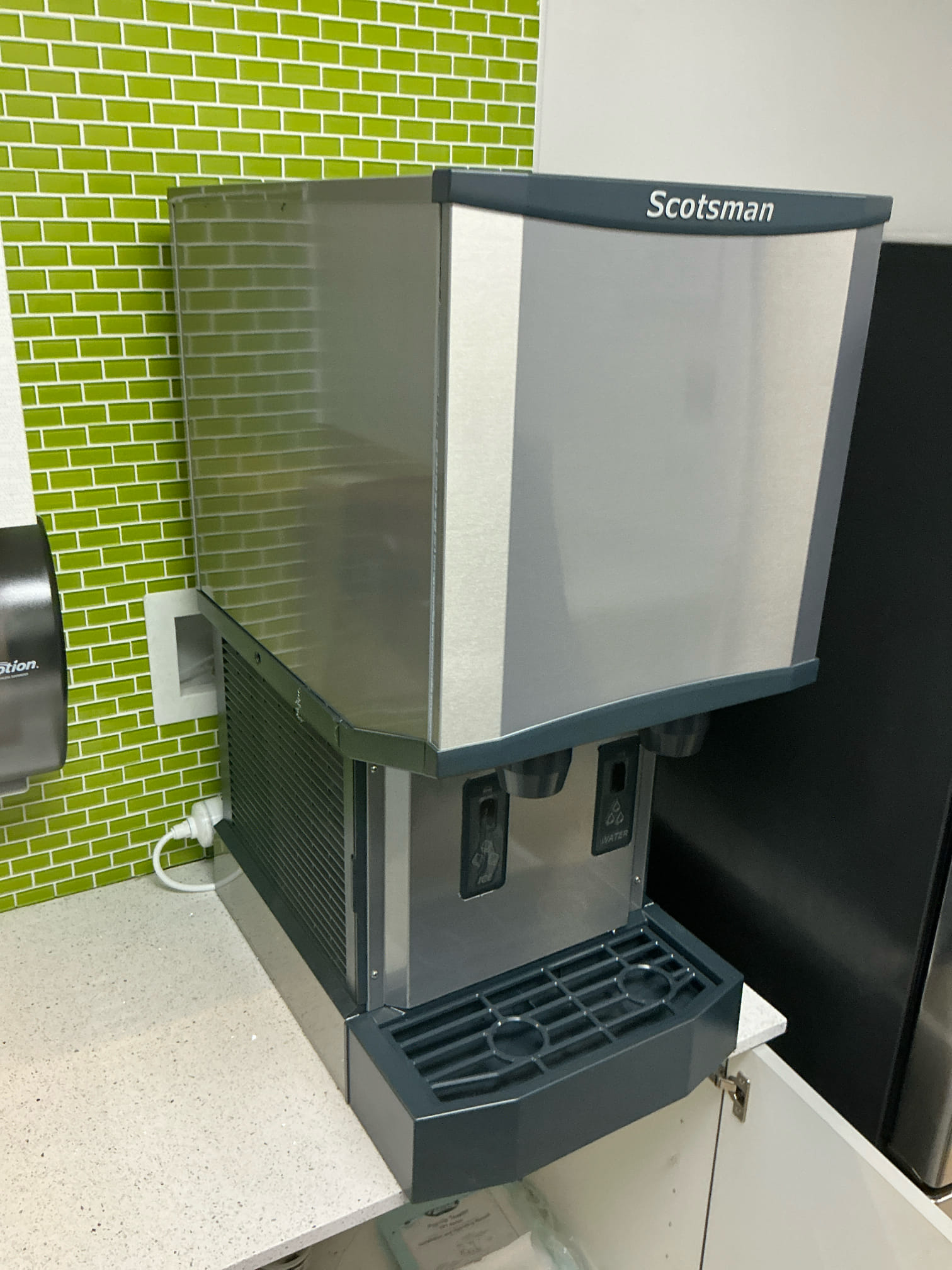

Keeping your commercial ice machine in top shape is essential for your business’s smooth operation. Whether you run a restaurant, hotel, or convenience store, unexpected breakdowns can disrupt service and cost you money.

An ice machine maintenance plan helps prevent costly repairs, ensures clean and safe ice, and keeps your equipment running efficiently all year round.

With regular upkeep, you reduce the chance of malfunctions like leaks, strange noises, or poor ice quality. At Memphis Ice, we’ve been helping businesses in the Mid-South since 1977 by providing reliable maintenance plans designed to give you peace of mind.

When your ice machine works well, you can focus on serving your customers without worrying about unexpected downtime.

What Are Ice Machine Maintenance Plans?

Ice machine maintenance plans help you keep your machine clean, safe, and working efficiently all year. They provide regular checkups, cleaning, and repairs so your ice maker can avoid costly breakdowns and stay reliable.

These plans are designed to fit your schedule and needs, giving you peace of mind.

Overview of Maintenance Plans

A maintenance plan is a scheduled service agreement for your commercial ice machine. It covers routine care like cleaning, sanitizing, and inspections to prevent buildup of scale and bacteria.

This keeps your ice tasting fresh and your machine running smoothly. Regular maintenance also means fewer emergency repairs and better compliance with health rules.

As a business owner, having a plan reduces downtime and surprises. It extends the life of your unit and protects your investment, especially in busy months.

Types of Maintenance Services

Maintenance plans vary but usually include several key services:

- Cleaning and Sanitizing: Removes mineral buildup and harmful germs.

- Component Inspection: Checks parts like filters, fans, and pumps.

- Performance Testing: Ensures the machine is producing the right amount of ice.

- Filter Replacement: Keeps water quality high for safer ice.

You can choose full-service plans that cover everything or limited plans focusing on cleaning only. Memphis Ice offers flexible options to match your business size and usage patterns.

How Maintenance Plans Work

When you sign up, a technician sets a service schedule, often quarterly. They visit your site to perform the agreed tasks, noting any issues.

These visits help detect small problems before they grow. Your plan may include priority scheduling and discounts on repairs.

You don’t have to worry about when to call for service — it’s already planned. Memphis Ice handles everything, so your ice machine keeps up with your business demands year-round.

Essential Benefits of Ice Machine Maintenance Plans

Proper care for your ice machine means it will work better, last longer, and keep your business running smoothly. You get reliable ice quality, avoid unexpected breakdowns, and manage your expenses more easily.

Increased Equipment Lifespan

Regular maintenance helps your ice machine stay in good working condition for many years. When parts are cleaned and checked often, you prevent buildup and wear that can cause damage.

This means your machine won’t need to be replaced as soon, saving you money in the long run. At Memphis Ice, we’ve seen how routine care can extend equipment life well beyond average expectations.

Ignoring maintenance can cause parts to fail early, putting you at risk of costly repairs or total breakdowns. A simple plan keeps everything running efficiently and protects your investment.

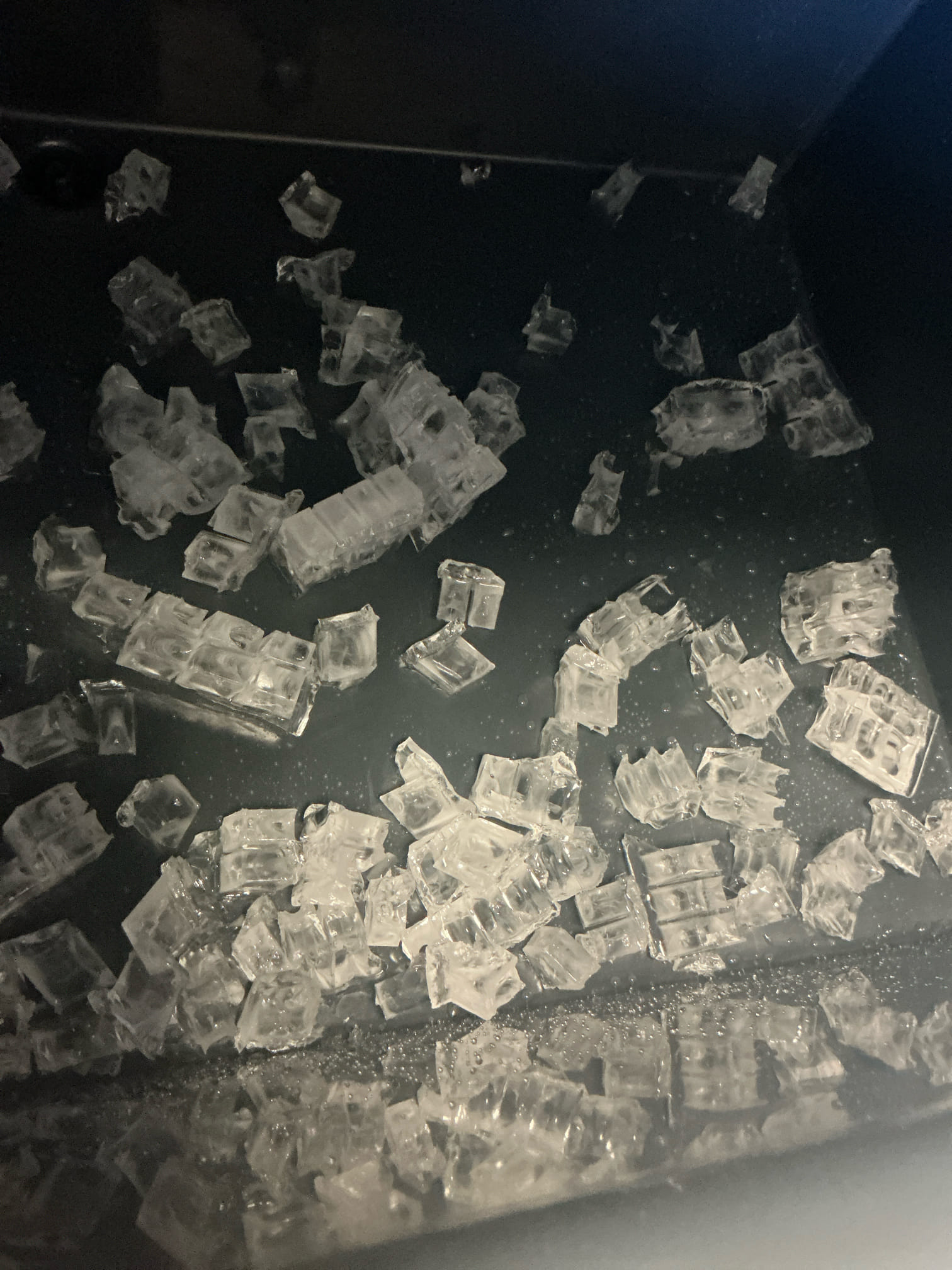

Consistent Ice Quality

Your customers or staff depend on clean, clear ice every time. If your machine isn’t maintained, dirt, scale, and bacteria can build up, causing poor ice quality and health risks.

Regular cleaning and inspection remove these contaminants, ensuring the ice stays fresh and safe. This is especially important for businesses like restaurants, bars, and hospitals where ice quality matters.

Maintenance also helps the machine produce ice at the right size and shape consistently. You get better service without worrying about off-quality ice harming your reputation.

Reduced Risk of Breakdowns

Unexpected breakdowns disrupt your operation and can mean lost sales or worse. Maintenance plans catch small issues before they become major problems.

Scheduled checks spot worn parts, leaks, or other faults that could cause a machine to stop working. Fixing these early prevents emergency repairs that are often costly and timely.

Sticking to a maintenance plan means your ice machine runs when you need it most. Memphis Ice makes sure your equipment gets the attention required to avoid downtime during busy seasons.

Predictable Maintenance Costs

With a maintenance plan, you pay a fixed or planned amount for service visits and repairs. This helps you budget easily and avoid surprise expenses for urgent fixes.

You’ll know when maintenance is coming and can plan around your business hours. Preventing major repairs also saves money by catching small faults early.

A predictable cost structure makes managing your ice machine’s care less stressful. You get professional help regularly without worrying about sudden breakdown bills getting in the way.

Operational Efficiency Improvements

Keeping your commercial ice machine in top shape helps boost how well it runs every day. When machines are clean and parts are checked regularly, you save energy, produce the right amount of ice, and avoid costly breakdowns.

Energy Efficiency Gains

Regular maintenance ensures your ice machine doesn’t waste energy. Dirt and buildup on condenser coils make the machine work harder, pushing electricity use higher.

Cleaning these parts keeps the unit running smoothly and lowers power bills. Checking refrigerant levels and replacing worn parts also helps the system maintain the right cooling balance.

When everything runs efficiently, your ice machine uses less water and electricity. That means lower costs for you, especially during hot months when ice demand spikes in Memphis and the Mid-South.

With consistent care, you avoid energy drains that come from equipment overworking. This makes your machine more reliable and cost-effective over time.

Optimal Ice Production Levels

Your ice machine needs regular checks to keep producing ice at the right rate. If components like water filters or sensors aren’t maintained, ice output can slow or become uneven.

This interrupts your service and affects your business reputation. Maintenance plans include timely cleaning and part replacements to ensure the machine matches your daily ice needs.

For example, busy restaurants and hospitals rely on a steady ice supply for food safety and patient care — any drop in ice production disrupts that flow.

Minimized Downtime

Breakdowns cost time and money. Preventive maintenance lets you fix small problems early, avoiding emergencies that shut down your machine unexpectedly.

Scheduling regular service visits means fewer unplanned repairs. When your ice machine runs smoothly, you stay focused on your business—not endless fixes.

Parts like pumps and compressors get inspected so they don’t fail during peak hours. This keeps downtime low, protecting your revenue.

Memphis Ice offers maintenance plans designed to keep your ice machine running year-round. That way, you won’t face delays or lose customers because of machine failures.

Health, Safety, and Compliance Advantages

Keeping your ice machine well-maintained helps protect your customers and staff. It also makes following local rules easier.

Clean, safe ice prevents health risks and keeps your business running without interruptions.

Improved Food Safety

Regular maintenance cleans and sanitizes your ice machine. This stops bacteria, mold, and other germs from growing inside it.

Dirty machines can cause contamination, risking your customers’ health. When your ice is safe, you reduce the chance of foodborne illness at your business.

This is especially important in places like restaurants, bars, and hospitals where ice is used daily. At Memphis Ice, we know clean ice machines mean peace of mind.

Keeping your equipment sterilized helps maintain the quality and safety of ice, so you never have to worry about what’s in it.

Easier Regulatory Compliance

Health codes require ice machines to meet strict cleaning and maintenance standards. Regular care makes it simpler to pass health inspections without issues.

Following FDA and local rules avoids fines or forced shutdowns. Maintenance plans also document cleaning schedules, which inspectors often ask to see.

By working with Memphis Ice, you ensure your ice machines meet all these requirements. This keeps your business in good standing and lets you focus on serving your customers, not paperwork.

Cost Savings and Financial Peace of Mind

Keeping your ice machine in good shape means spending less on big repairs and unexpected fixes. You also avoid costly downtime that can hurt your business.

The right maintenance plan helps protect your investment, extending the life of your equipment and making your daily operations smoother.

Lower Repair Expenses

Regular maintenance stops small problems from becoming expensive repairs. When your ice machine is serviced often, technicians catch issues early.

This saves you from costly parts replacement and long service calls later. For example, cleaning scales and checking hoses reduce wear and tear.

Membranes and filters replaced on schedule help your machine run efficiently without breaking down. By investing a little in preventive care, you avoid surprise repair bills that can disrupt your cash flow.

At Memphis Ice, we’ve seen how planned maintenance keeps costs predictable and manageable.

Extended Equipment Warranty

Many ice machine manufacturers require regular servicing to keep their warranties valid. When you follow a maintenance plan, you protect your coverage.

If something does break, having a valid warranty can cover repairs and parts, which saves you money. Missing scheduled maintenance means you might lose this protection, leaving you to pay out of pocket.

A simple checklist of routine tasks preserves the warranty and helps your machine last longer. Memphis Ice can help you track and meet these service requirements, so your warranty remains intact and useful.

Reduced Emergency Service Calls

Emergencies are costly — both in emergency fees and downtime. When your ice machine stops suddenly, you lose ice production, and that impacts your business.

Regular maintenance lowers the chance of unexpected breakdowns by keeping your machine clean and adjusted for peak performance. This means fewer emergency service calls and less stress when things stay on schedule.

You save money by avoiding 3-4 times higher costs that emergency repairs can bring. Our maintenance plans at Memphis Ice include quick, reliable check-ups so your ice machine is ready when you need it most.

Convenience and Professional Support

Having a maintenance plan means you won’t have to worry about unexpected breakdowns or complicated repairs. You get regular care, expert help when you need it, and clear records of every service done.

This keeps your ice machine running smoothly without adding stress to your busy day.

Scheduled Preventive Maintenance

With scheduled preventive maintenance, your ice machine gets checked and cleaned on a set timetable. This stops problems before they start and helps your machine work at its best.

A good maintenance plan includes tasks like sanitizing the ice bin, cleaning the water filter, and inspecting mechanical parts. Doing these regularly lowers the chances of malfunctions, protects the quality of the ice, and extends your machine’s life.

You don’t have to remember when to schedule service — it’s all handled for you. Memphis Ice sets up visits that fit your business hours so you won’t lose valuable operating time.

Access to Expert Technicians

When you have a maintenance plan, you get priority access to technicians who know ice machines inside and out. These pros respond quickly to issues and fix them properly the first time.

Expert help means fewer interruptions and less downtime. Your machine stays reliable even during busy seasons.

The technicians also offer advice on keeping your ice maker clean and efficient. Memphis Ice provides certified techs familiar with local health codes and equipment standards.

You benefit from their training and years of experience, so your ice remains safe and ready to use.

Documentation and Service Records

A maintenance plan keeps detailed records of every visit and repair. This paperwork helps track what’s been done and when, making it easier to plan future service.

Having documentation also supports compliance with health regulations, showing inspectors your ice machine is well cared for. It helps avoid fines or forced shut-downs.

You’ll receive clear reports after each service, so you always know your machine’s condition. This transparency makes it easy to budget for upkeep and spot recurring issues early.

Choosing the Right Ice Machine Maintenance Plan

Picking the best maintenance plan means more than just scheduling cleanings. You want a service provider who knows your type of ice machine and can work with your business needs.

Plus, your plan’s timing should match how often your machine runs and how much ice you use.

Evaluating Service Providers

When choosing a service provider, look for experience with commercial ice machines, especially in your region. A local company like Memphis Ice knows the climate and common issues businesses face in the Mid-South.

Fast response times matter because downtime hurts your operation. Check if the provider offers clear, detailed maintenance plans that fit your budget and schedule.

Their team should use manufacturer-approved cleaning agents and follow proper procedures to avoid damage or contamination. Reading customer testimonials or asking for references helps you find trustworthy technicians.

Customizing Maintenance Frequency

Your ice machine’s maintenance frequency should match your business’s ice demand. High-use locations like restaurants or hospitals might need weekly or monthly cleanings.

Lower-use sites may manage with quarterly visits. Make sure your plan includes regular tasks like cleaning, sanitizing, checking temperature settings, and inspecting parts for wear.

Adjust frequency based on machine performance and seasonality—summer often means heavier workloads. Reviewing performance logs and inspection results with your provider helps fine-tune the schedule.

Frequently Asked Questions

Keeping your ice machine clean, checked, and running on a schedule helps avoid surprises and keeps the ice safe and fresh. Knowing how maintenance works can help you make the best decisions for your business’s needs and budget.

What are the key steps involved in a regular ice machine maintenance routine?

You should start by cleaning the machine’s parts to stop buildup and bacteria. Inspect water filters and replace if needed to keep water clean.

Check the machine for leaks, unusual noises, and ice production levels. Regularly sanitize the ice bin and surrounding areas.

How can a maintenance plan extend the lifespan of an ice maker?

Routine care prevents small problems from turning into big repairs. It keeps parts working smoothly and reduces wear over time.

This lowers the risk of breakdowns, letting your ice maker last longer and work more efficiently.

What are the common issues prevented by routine ice machine check-ups?

Regular checks catch leaks, strange noises, and slow ice production early. Cleaning stops clogs and bad tastes in the ice.

This helps avoid costly downtime during busy hours when you need ice the most.

Why is preventive care crucial for the efficiency of ice machines?

Preventive care means your machine uses less energy and produces more ice. Dirty parts and blocked water flow can cause the machine to work harder and waste power.

Keeping it clean and serviced keeps things running smoothly.

How often should professional servicing be scheduled for an ice maker?

For most commercial machines, a professional should check and clean your ice maker at least twice a year. If you use your machine nonstop, more frequent visits could be better to maintain top performance.

Memphis Ice can help set the right schedule based on your operation.

Can regular ice machine maintenance impact energy consumption and costs?

Yes, a well-maintained ice machine uses less electricity and water. It avoids overworking components that can raise bills.

Proper cleaning and service help you save money. Regular maintenance keeps your machine cost-effective year-round.

Recent News

Common Ice Machine User Mistakes and How to Prevent Them for Smooth Operation

Tips for Improving Airflow Around Commercial Refrigeration Units to Boost Efficiency and Longevity

Tips for Organizing Multi-Zone Walk-In Coolers Made Easy and Efficient

Tips for Organizing Walk-In Coolers for Faster Kitchen Workflow and Efficiency

Tips for Organizing Your Walk-In Freezer for Safety and Efficiency Made Easy and Practical

Tips for Preparing Cold Storage Before Major Events Friendly Guide to Staying Organized and Efficient