proudly serving

the mid-south

When To Replace Your Ice Machine: Simple Signs and Tips to Know

Knowing when to replace your ice machine can save you time, money, and headaches. If your machine is showing signs like slow ice production, strange noises, or frequent breakdowns, it’s probably time to consider a replacement.

These issues disrupt your daily operations and can lead to costly repairs and lost business.

Your ice machine works hard every day, especially in busy restaurants, bars, or healthcare settings across the Mid-South. Regular maintenance helps, but even the best care can’t stop wear and tear forever.

When your machine is older or no longer keeping up with demand, upgrading ensures smooth, reliable service.

At Memphis Ice, we’ve been keeping businesses cool since 1977. We understand how important dependable ice production is for your operation.

Key Signs Your Ice Machine Needs Replacement

Your ice machine is vital for smooth business operations. When it starts showing trouble, you’ll notice specific changes that affect production and ice quality.

Watching for these signs helps you decide if it’s time to replace your machine before disruptions hit.

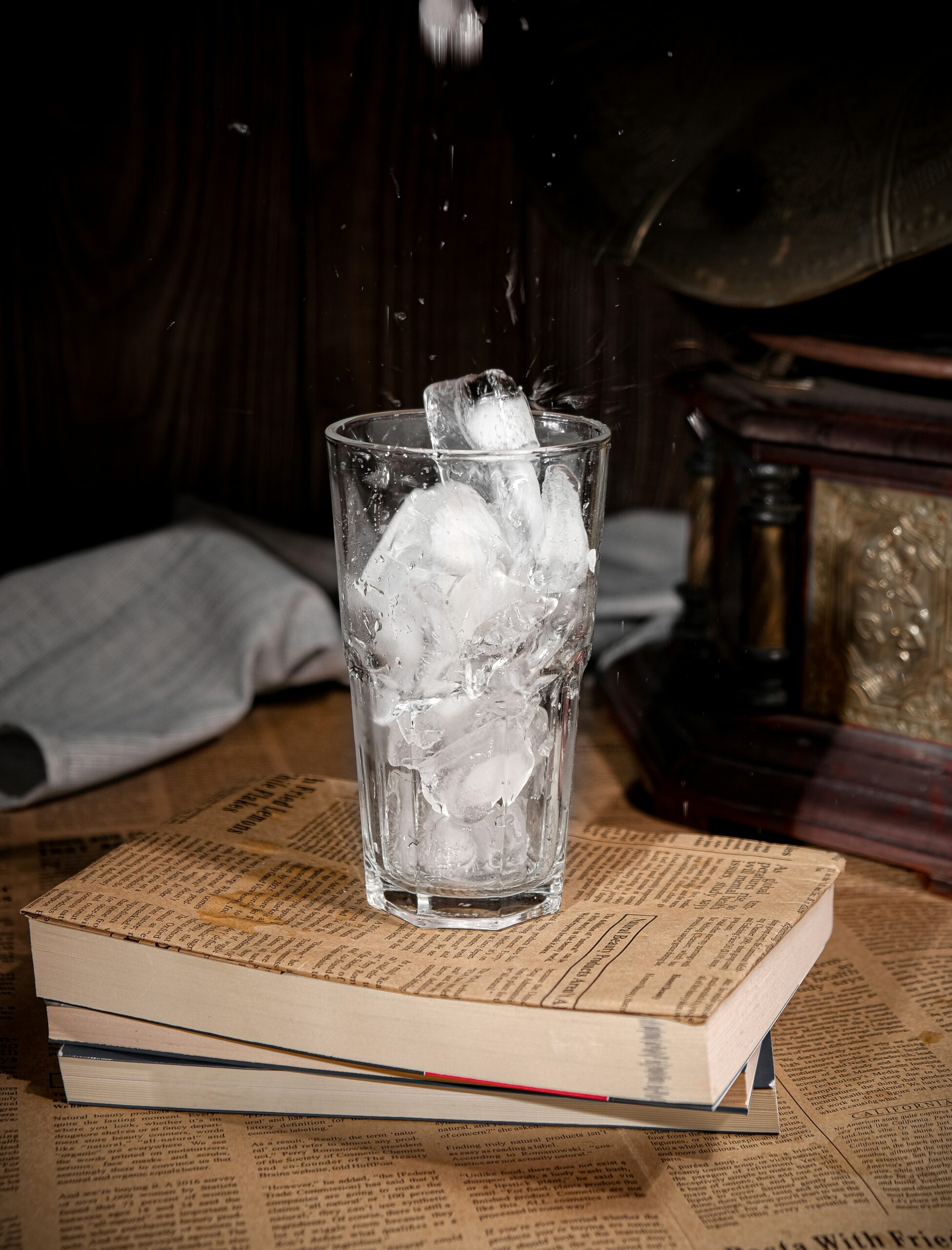

Decreased Ice Production

If your ice machine is making less ice than usual, it’s a clear warning. A slower output means your machine is struggling.

This can happen because of internal wear, clogged filters, or failing components. Over time, parts degrade and reduce efficiency.

You might also see ice building up unevenly or stopping mid-cycle. If cleaning and regular maintenance don’t improve output, your machine may be aging out.

Reduced ice supply affects your service speed and customer satisfaction. If your business relies on steady ice, act quickly.

Frequent Breakdowns

When your ice machine needs repairs more often, it’s costing you time and money. Frequent breakdowns signal the machine’s days are limited.

If you’re calling for repairs regularly for the same issues, it’s a red flag. Older machines may have parts that are no longer available or too expensive to fix.

Constant interruptions hurt your workflow. Investing in a new machine often saves you from costly downtime and stress.

Unusual Noises

Strange noises like grinding, clanking, or loud buzzing aren’t normal. These sounds usually mean internal parts are failing or clogged.

If your ice machine starts making new noises, something isn’t right. Ignoring these sounds can lead to bigger problems like full mechanical failures.

When you hear persistent unusual sounds, consider replacement to avoid surprise breakdowns.

Declining Ice Quality

The ice your machine makes should be clear, odorless, and taste fresh. If the ice looks cloudy, smells, or tastes strange, it’s a warning sign.

Poor ice quality can come from mold buildup, mineral deposits, or dirty filters. Sometimes cleaning helps, but if the issue keeps returning, the machine may be too worn.

Serving bad ice hurts your reputation, especially in food or healthcare settings. If quality declines and cleaning doesn’t fix it, replacing the machine is the safest choice.

Performance and Efficiency Considerations

Over time, your ice machine’s performance can slow down and efficiency may drop. This can lead to higher energy bills, increased repair costs, and wasteful water use.

Paying attention to these issues helps you decide when it’s time to replace your machine.

Increased Energy Consumption

When your ice machine ages, it often uses more electricity to keep running. Older parts become less efficient, causing the compressor and motors to work harder.

This drives up your energy costs and can strain your power system. If you notice a spike in your utility bills without changes in ice usage, your machine might be the reason.

Increased energy consumption signals wear in key components, which could fail and cause breakdowns. Replacing an old machine can reduce energy bills and make your operation more reliable.

Rising Maintenance Costs

Older ice machines often require more frequent repairs. Parts wear out and need replacement more often.

These rising maintenance costs add up quickly and interrupt your business flow. If your repairs are becoming regular or the service bills grow higher, consider the cost of keeping your machine versus replacing it.

Newer models often come with warranties and require less upkeep. This means less downtime and fewer unexpected expenses for you.

Poor Water Usage Efficiency

Commercial ice machines need a steady water supply to work well. Over time, mineral buildup and clogged filters can reduce their water efficiency.

This causes your machine to use more water to make the same amount of ice. Poor water efficiency increases water bills and affects ice quality and machine lifespan.

Signs like water leaks or less ice output often mean your ice maker is struggling to use water properly. Upgrading to a new model could save water and improve ice production.

Age and Service Life of Ice Machines

Knowing how long your ice machine can last and what to watch for in its parts helps you plan for repairs or replacement.

Ice machines have different lifespans depending on their type, and certain worn components often signal the need for service.

Typical Lifespan by Ice Machine Type

Most commercial ice machines last between 7 to 12 years with proper care.

- Cube and nugget ice machines tend to last around 10 years.

- Flake ice machines last 7 to 10 years but may need more frequent maintenance.

- Modular machines can reach 12 years or more, depending on use and upkeep.

Regular cleaning and maintenance help stretch this lifespan. Skipping routine care speeds up wear and reduces efficiency.

When an ice machine hits the 8-10 year mark, start monitoring it more closely for signs of trouble.

Signs of Aging Components

Some parts wear out faster and show clear signs before a full breakdown. Look for:

- Slow ice production: The condenser or evaporator may be losing function.

- Strange noises: Motors or compressors might be failing.

- Water leaks: Worn seals or clogged drain lines could be the cause.

- Unusual taste or smell in ice: Buildup inside the machine or dirty filters may be to blame.

If you notice these signs, have a technician inspect your ice machine. Early repairs can avoid costly downtime and keep your service running smoothly.

Health and Safety Concerns

Keeping your ice machine clean and safe is crucial for your business. Watching for common sanitation problems and signs of mold or bacteria build-up helps protect your customers and avoids health code violations.

Frequent Sanitation Issues

If you find yourself cleaning your ice machine more often than usual, or notice the cleaning isn’t working, your machine may be struggling. Frequent sanitation issues happen when parts like the water reservoir or ice storage bin get dirty quickly.

This dirt can cause strange tastes or odors in your ice. It also strains the machine, making it work harder to produce clean ice.

When regular cleaning stops improving these issues, you might need to replace worn-out parts or the whole machine. Staying on top of a cleaning schedule can delay this, but persistent problems deserve a closer look.

Mold or Bacteria Build-Up

Mold and bacteria grow easily in warm, wet areas like inside an ice machine that hasn’t been cleaned well. If you notice slimy deposits, dark spots, or any strange smells, these are signs of contamination.

This build-up affects ice quality and can pose health risks to your customers. It also causes your machine to fail sooner because grime clogs filters and pumps.

If mold or bacteria keep returning even after deep cleaning, replacement may be necessary to keep your operation safe and compliant with health standards.

Cost-Benefit Analysis of Repair Versus Replacement

Deciding whether to repair or replace your ice machine depends on how much you spend over time and how those costs affect your daily business.

Weighing the financial impact against the machine’s performance helps you prevent surprises and keep your operation smooth.

Comparing Long-Term Costs

Repairs might seem cheaper at first, especially for minor fixes. But if your machine breaks down often, repair bills add up quickly.

Parts wear out, and some might be hard to find for older models, making fixes more expensive. A newer machine usually uses less energy and water, saving money on utility bills.

Modern machines often need less maintenance, reducing ongoing costs.

Key costs to consider:

- Repair fees and parts

- Downtime losses

- Energy and water efficiency

- Maintenance expenses

Calculating these can show when replacement costs balance or beat repair spending.

Impact on Business Operations

Frequent ice machine breakdowns disrupt your service and slow down staff. Running out of ice during busy hours affects food prep, customer satisfaction, and staff stress levels.

A reliable machine means fewer service interruptions. It keeps your team productive and customers happy.

Downtime can also affect your brand, especially if you serve high volumes in restaurants or healthcare. Think about how much downtime costs your business daily.

Sometimes, investing in a new machine avoids hidden losses you might not see in repair bills alone.

When to Upgrade for New Features

Upgrading your ice machine can bring more than just fresh ice. New models often include features that improve water quality and automation.

These upgrades can save you time, reduce maintenance, and keep your operation running smoothly.

Advanced Filtration Systems

Water quality is key to making good ice. New ice machines offer advanced filtration systems that remove more impurities than older models.

These filters reduce chlorine, sediment, and minerals that can cause bad taste or buildup inside your machine. An improved filtration system means your ice will taste cleaner and stay fresher longer.

It also helps protect parts like the evaporator and condenser from scaling or corrosion. This lowers your maintenance needs and extends the life of your machine.

If you’ve noticed off-flavors or white spots on your ice, upgrading the filtration can solve those problems. Advanced filters can also improve your compliance with health codes by providing safer ice for customers and patients.

Improved Controls and Automation

Modern ice machines come with smarter controls and automation features. These systems monitor ice production and water levels, and they alert you when maintenance is needed.

This reduces guesswork and helps avoid unexpected breakdowns. Automated cleaning cycles make routine maintenance easier and keep your machine hygienic without manual effort.

Smart controls can adjust ice output based on demand, saving energy during slow periods. Clear status indicators or remote monitoring help you spot problems early.

This keeps your operation running without surprises and allows quick service when needed. If downtime affects your business, upgrading to automated controls is worth considering.

Eco-Friendly Replacement Options

When it’s time to replace your commercial ice machine, you can choose options that save energy and reduce waste.

Switching to an Energy Star certified model can cut your energy use by up to 15%. That means lower utility bills and less environmental impact.

Many newer ice machines have water-saving settings and energy-efficient compressors. These features help reduce daily water and electricity use.

They often run more quietly and need less maintenance.

Consider machines with recyclable parts or those built to last longer. This reduces waste and the need for frequent replacements.

Some suppliers, including local ones, may offer trade-in programs. You can dispose of your old unit responsibly through these services.

Using water filters can also improve ice quality and protect your machine. Filters reduce mineral buildup, which means fewer repairs and a longer machine life.

Here’s a quick look at the benefits:

| Feature | Benefit | Eco Impact |

|---|---|---|

| Energy Star Certification | Lower energy bills | Less greenhouse gas emissions |

| Water-saving technology | Reduced water use | Conserves local water sources |

| Durable, recyclable parts | Fewer replacements needed | Less landfill waste |

| Built-in filtration | Cleaner ice, fewer repairs | Longer machine lifespan |

When you work with a local company, like us here in the Mid-South, you get advice on the best eco-friendly models for your business.

We help you find options that fit your needs and budget while keeping sustainability in mind.

Planning for a Smooth Transition

Replacing your commercial ice machine takes some planning to avoid disruptions.

Start by setting a clear timeline for when the new unit will arrive and be installed. This helps you coordinate with your team and local service providers.

Make a checklist of key tasks:

- Schedule removal of the old machine

- Arrange delivery and installation of the new unit

- Plan for any plumbing or electrical work needed

Let your staff know about the change so they can prepare. This reduces surprises and keeps your operation running smoothly.

If possible, schedule the switch during slower hours or days. You might want to rent an ice machine temporarily to cover your needs.

Work with a trusted service partner who knows your business and the local area. They can help with timely installation and maintenance plans that fit your schedule.

Frequently Asked Questions

Knowing when to replace your ice machine depends on its performance, repairs, and age.

Signs like reduced ice output, frequent breakdowns, and costly fixes can mean you should consider a new unit.

How can I tell if my ice machine is due for a replacement?

If your machine makes strange noises, produces less ice, or leaks water often, these are clear warning signs.

When repairs become more frequent and expensive, replacement may be the better option.

What is the average lifespan of a refrigerator’s built-in ice maker?

Built-in ice makers typically last around 5 to 7 years.

Proper maintenance can stretch this, but after that, efficiency usually drops and repairs increase.

At what point should I consider replacing a portable ice maker?

Portable ice makers usually last 3 to 5 years under regular use.

If it struggles to keep up or breaks down regularly, replacing it can save time and money.

Are there common signs that indicate a commercial ice maker needs replacing?

Yes.

These include slow ice production, water leaks, frequent mechanical failures, and ice that tastes or smells off. Machines over 7 years old with these issues often need replacing.

Is it cost-effective to repair an ice maker or should I just replace it?

If repair costs exceed half the price of a new machine or if issues happen frequently, replacement is usually more cost-effective.

Ongoing repairs can also disrupt your operations.

What maintenance tips can extend the life of my home ice machine?

Clean filters regularly. Schedule professional service at least twice a year.

Keep the machine free from clogs. Maintain the proper temperature to help it run efficiently and last longer.

Recent News

Tips for Extending Lifespan of Walk-In Cooler Doors Friendly Maintenance and Care Guide

Tips for Extending the Life of Commercial Refrigeration Units with Easy Maintenance Habits

Emergency Walk-In Freezer Repair Tips to Keep Your Business Running Smoothly

Emergency Cold Storage Solutions for Events Made Easy and Reliable

Common Reasons Ice Machines Run Loud and How to Fix Them Easily

Common Ice Machine User Mistakes and How to Prevent Them for Smooth Operation