proudly serving

the mid-south

Top Reasons Ice Machines Fail and How to Fix Them Easily

When your ice machine calls it quits, everything else seems to stall. If you’re running a restaurant, a hospital, or a bar, you know that a busted ice maker just isn’t an option. The top reasons ice machines fail usually involve water supply snags, clogged filters, or electrical hiccups—all common but fixable if you’re on top of things.

Catching trouble early is half the battle. Slow ice, weird noises, or off-tasting cubes? Those are your warning lights. At Memphis Ice, we’ve been keeping Mid-South businesses cool since 1977, so we get how crucial steady ice is for your day-to-day.

You’re not on your own with ice machine headaches. A little routine care and quick service can spare you a world of hassle. Here’s what usually goes wrong—and how you can dodge disaster.

Common Mechanical Failures

Mechanical bits inside your ice machine sometimes give up, stalling or slowing your ice supply. Knowing which parts to check first can get you back in business fast.

Compressor Malfunctions

The compressor is basically the heart of the machine, pumping refrigerant to chill water into ice. If it fails, you’re not getting any ice.

You might hear odd sounds, feel the machine getting hot, or notice it’s running but not cooling. Sometimes, a dirty fan or clogged coils force the compressor to work too hard and burn out.

When the compressor acts up, it’s time to call a pro. These repairs can get tricky. Regular cleaning and checkups help keep things humming.

Evaporator Issues

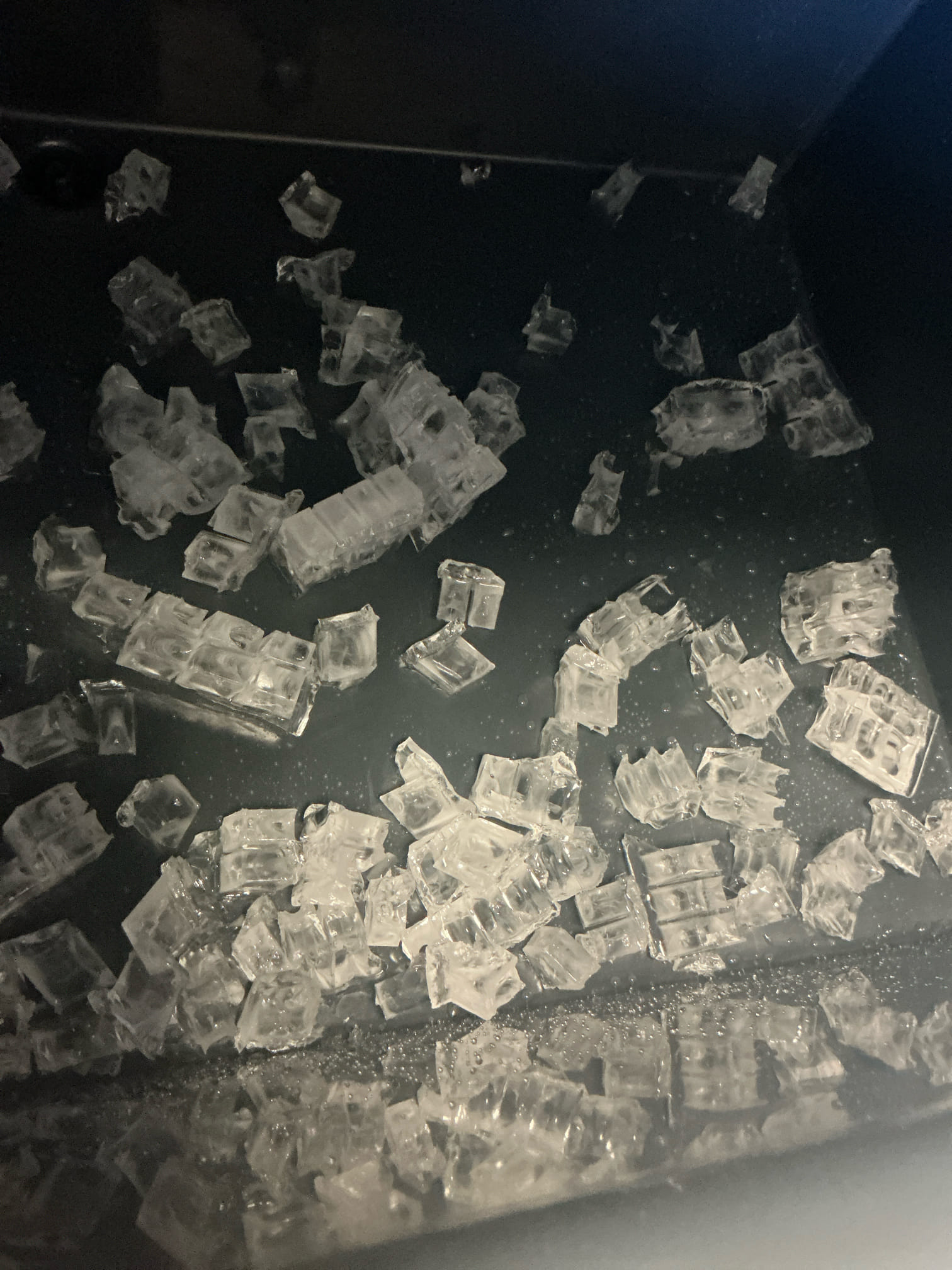

Ice forms on the evaporator, so problems here mean less ice or weird-shaped cubes. Hard water and minerals tend to build up, leading to poor ice quality.

Cloudy, tiny, or slow ice? Peek at the evaporator for gunk or cracks. Sometimes, frozen water inside can even crack or leak, which stops ice production altogether.

Cleaning the evaporator and checking for leaks really does help. We push this in our maintenance plans because it’s way cheaper than a big repair.

Broken Valves

Valves handle water flow. If one breaks or sticks, water can’t make it where it needs to go. That leads to slow ice production or no ice at all.

You might hear water running nonstop or spot leaks. Stuck valves can even flood the machine.

Swapping a bad valve is usually simple, but catching it early is key. Regular checkups really help here.

Worn Motors

Motors power the fans and pumps. When they wear down, you get weird noises, slow ice, or sometimes a total shutdown.

Struggling motors can overheat and burn out. Listen for humming or sudden stops and starts.

Having a tech check the motors during routine service can save you from a surprise breakdown. Our Memphis Ice crew is always ready to help keep those motors in shape.

Water Supply Problems

Ice machines need a steady, clean water flow. If the water supply is weak or dirty, ice production slows or stops. Fix water issues fast to keep things running.

Clogged Water Filters

Filters catch dirt before it hits your machine. When they clog, water flow drops and ice output tanks.

Change filters often. If the ice tastes funny or looks cloudy, check the filter first. Clogged filters strain the machine and can lead to bigger repairs. We always tell folks to keep spare filters handy, especially when things get busy.

Low Water Pressure

If your water pressure drops, the machine can’t fill fast enough. That means slow ice or even a shutdown.

You’ll want pressure between 20 and 80 psi—check your manual. Leaks, closed valves, or city water issues can cause problems. A cheap gauge will tell you what’s up, and you can adjust or call your provider if needed.

Supply Line Blockages

Blockages in the supply line cut off water or slow it down. Mineral buildup, debris, or even a kinked pipe can do it.

Look over your supply line for leaks, bends, or gunk. Hard water around Memphis makes mineral buildup pretty common. Sometimes a flush or swapping out a bad section does the trick. If you’re lost, our techs can help get things flowing again.

Electrical and Control System Faults

Electrical and control issues stop ice machines in their tracks. These problems can cause random shutdowns or poor ice output. Spotting them early can save you money and hassle.

Faulty Wiring

Bad wiring is a sneaky culprit. Wires can loosen, corrode, or get fried by heat and moisture, cutting off power or making the machine behave oddly.

If your ice maker keeps shutting off or trips the breaker, check for frayed wires or burn marks. Turn it off and call someone who knows what they’re doing.

We always stress checking connections during maintenance. It’s a simple thing that keeps your machine safe.

Thermostat Failures

The thermostat keeps things cold inside. If it fails, you get too little ice or none at all. Sometimes, the evaporator freezes up, or water won’t chill enough.

If the machine runs but barely makes ice, or the cubes melt fast, the thermostat might be shot. Cooling cycles that don’t make sense are another hint.

Replacing a thermostat isn’t too bad, but a tech should handle it to get the settings right. A good thermostat means steady ice, no surprises.

Sensor Malfunctions

Sensors tell the machine when to start or stop making ice. If one breaks or gets confused, you might get slow ice, no ice, or a machine that never stops running.

A busted water level sensor can keep water from coming in. A bad bin full sensor might pause the machine for no reason. Either way, you’re left short on ice or wearing out parts for nothing.

If you notice weird behavior—strange noises, ice that comes and goes—get the sensors checked. A pro can swap them out and get you back on track.

Poor Cleaning and Maintenance

Skipping routine cleaning leads to all sorts of headaches. Buildup and dirty parts just make your machine work harder and break faster. Ice quality drops, and repairs get expensive.

Mineral Scale Buildup

Hard water leaves mineral gunk inside the machine. This scale blocks water flow and kills efficiency. It also puts extra stress on the compressor and other moving parts.

Slower ice or cloudy cubes usually mean mineral buildup. Descale with approved cleaners every few months. It’s not glamorous, but it keeps ice clear and the machine happy.

Dirty Condenser Coils

The condenser coils need to stay clean to cool properly. Dust and grime make it tough for the system to dump heat, so it overheats or just stops making ice.

Add coil cleaning to your regular routine. Use a soft brush or vacuum to clear away the dirt. Clean coils make everything run smoother and help your machine last longer.

Neglected Routine Inspections

Skipping regular checks lets small problems turn into big ones. Checking filters, hoses, sensors, and wires helps you spot trouble before it gets ugly.

Make a simple checklist—leaks, weird sounds, warning lights. We’ve seen plenty of machines bounce back after a quick tune-up. Staying on top of things means fewer emergencies and less stress.

Environmental and Location-Related Issues

Where you put your ice machine matters—a lot. Temperature, airflow, and nearby heat sources all mess with performance. Overlooking these details can cause failures you didn’t see coming.

High Ambient Temperatures

If the air around your machine gets too hot, it has to work overtime to make ice. This wears out the compressor and other parts way faster.

Keep the machine in a spot below 90°F (32°C). Kitchens and hot equipment nearby can push temps up and slow production.

A climate-controlled room is ideal. We always suggest a cool, shaded spot away from sunlight and heat to keep things running longer.

Improper Ventilation

Good airflow is non-negotiable. Without it, heat builds up and the machine struggles. The condenser can’t dump heat, so efficiency drops and parts fail.

Don’t cram your ice maker into a tight space. Leave at least 6 inches on all sides for air to move. Clean vents and grilles often—dust can block them fast.

High humidity and bad airflow also mean more moisture, which leads to rust or electrical headaches.

Placement Near Heat Sources

Stick your ice maker next to an oven, and you’re asking for trouble. Extra heat makes the cooling system work too hard, risking breakdowns.

Heat sources nearby can raise the temperature around your machine and kill ice output. The compressor and other parts might not last as long.

Keep some distance from ovens, stoves, or hot pipes. If you’re tight on space, try a barrier or some insulation. We’re happy to help you find the best spot.

Improper Usage and User Error

Sometimes it’s just how the machine gets used. Simple mistakes can cause breakdowns or bad ice. Avoid these common slip-ups to keep your machine happy.

Overloading the Ice Machine

Trying to grab too much ice at once? That stresses the machine and slows everything down, or worse, breaks it. Every ice maker has a limit—ignore it and you’ll pay for it later.

Too much ice can block sensors or jam moving parts, setting off error codes or shutting things down. Know your machine’s daily output and don’t push it past that.

Incorrect Settings

Wrong settings can make a mess. Setting the machine to pump out ice too fast or at the wrong temperature strains the system. You end up with small, cloudy cubes or a machine that wears out early.

Some machines let you tweak cycle times or ice size—if you’re not sure, check the manual or give us a call. Getting the settings right makes a real difference.

Unauthorized Repairs

DIY fixes often make things worse. The wrong tools or parts can damage the machine or spark electrical problems. That means bigger bills and more downtime.

Let the pros handle repairs. Memphis Ice has the know-how to keep your machine safe and up to code. Skip the guesswork and protect your investment.

Manufacturer Defects and Age-Related Wear

Sometimes, ice machine issues start before you even plug it in. Factory defects—like shoddy wiring, weak seals, or subpar parts—can lead to early breakdowns. Spotting these problems early on? That’s a lifesaver, honestly.

As time ticks by, normal wear and tear starts to show. Compressors, fans, and pumps get tired after years of work. Rubber gaskets dry out, crack, and suddenly you’re dealing with leaks or the machine just doesn’t cool like it used to. It’s just what happens, especially if your machine’s been working overtime during the busy months.

You might notice:

- Slow ice production

- Weird noises or shaky vibrations

- Leaks or frost showing up

- Cloudy or funky-tasting ice

Spot any of these? Might be time to schedule maintenance or call for repairs. At Memphis Ice, we’ve been helping local businesses keep their ice flowing for nearly five decades. Regular check-ups can catch little problems before they turn into wallet-draining disasters.

No machine lasts forever—let’s be real. Parts wear out, and sometimes hidden factory issues just catch up with you. Staying on top of service keeps your investment safe and helps you avoid sudden breakdowns. If you count on your ice machine every day, don’t put off getting help from folks who know what they’re doing.

Frequently Asked Questions

Ice machines quit for all sorts of reasons—sometimes it’s just a simple water issue, other times it’s an electrical gremlin. Figuring out what’s wrong and how to fix it can save you some headaches (and cash).

What are common issues that cause commercial ice machines to stop working?

You’ll often run into clogged water filters, busted control arms, or electrical hiccups. Sometimes, the machine’s safety features will shut everything down after a power or water glitch.

How can I troubleshoot an ice maker that’s not producing ice?

First, check if the control arm’s jammed or broken. See if there’s a water supply problem—low pressure or a clogged filter, maybe. And yeah, make sure the machine actually has power and hasn’t tripped a breaker.

What maintenance steps are crucial to prevent ice machine malfunctions?

Keep it clean and swap out those filters before they get gross. Bring in a pro at least twice a year. Take a look at moving parts like the control arm and make sure nothing’s busted.

Why is my ice machine producing small or malformed ice cubes?

Usually, that’s low water flow or gunk in the water supply. Worn parts inside the machine can mess with cube shape too. A good cleaning and a quick service call usually sorts it out.

Can water supply issues lead to ice machine failures?

Absolutely. Low water pressure, dirty water, or a supply interruption can all shut down ice production. Keeping a steady, clean water flow is pretty much non-negotiable if you want your machine to work.

What signs should I look for to indicate my ice machine needs servicing?

Keep an ear out for weird sounds or odd beeping—machines love to complain when something’s off. If your ice production starts dragging or you notice too much ice piling up, that’s a red flag. Sometimes the thing just shuts down more than usual, which is never a good sign. Honestly, getting Memphis Ice to check it out now and then can save you a headache later.

Recent News

Emergency Cold Storage Solutions for Events Made Easy and Reliable

Common Reasons Ice Machines Run Loud and How to Fix Them Easily

Common Ice Machine User Mistakes and How to Prevent Them for Smooth Operation

Tips for Improving Airflow Around Commercial Refrigeration Units to Boost Efficiency and Longevity

Tips for Organizing Multi-Zone Walk-In Coolers Made Easy and Efficient

Tips for Organizing Walk-In Coolers for Faster Kitchen Workflow and Efficiency