proudly serving

the mid-south

Restaurant Equipment Maintenance Plans for Smooth and Efficient Kitchen Operations

Keeping your restaurant equipment in good shape is essential to running your business smoothly. A well-planned maintenance plan helps prevent costly breakdowns, saves you time, and keeps your kitchen operations on track.

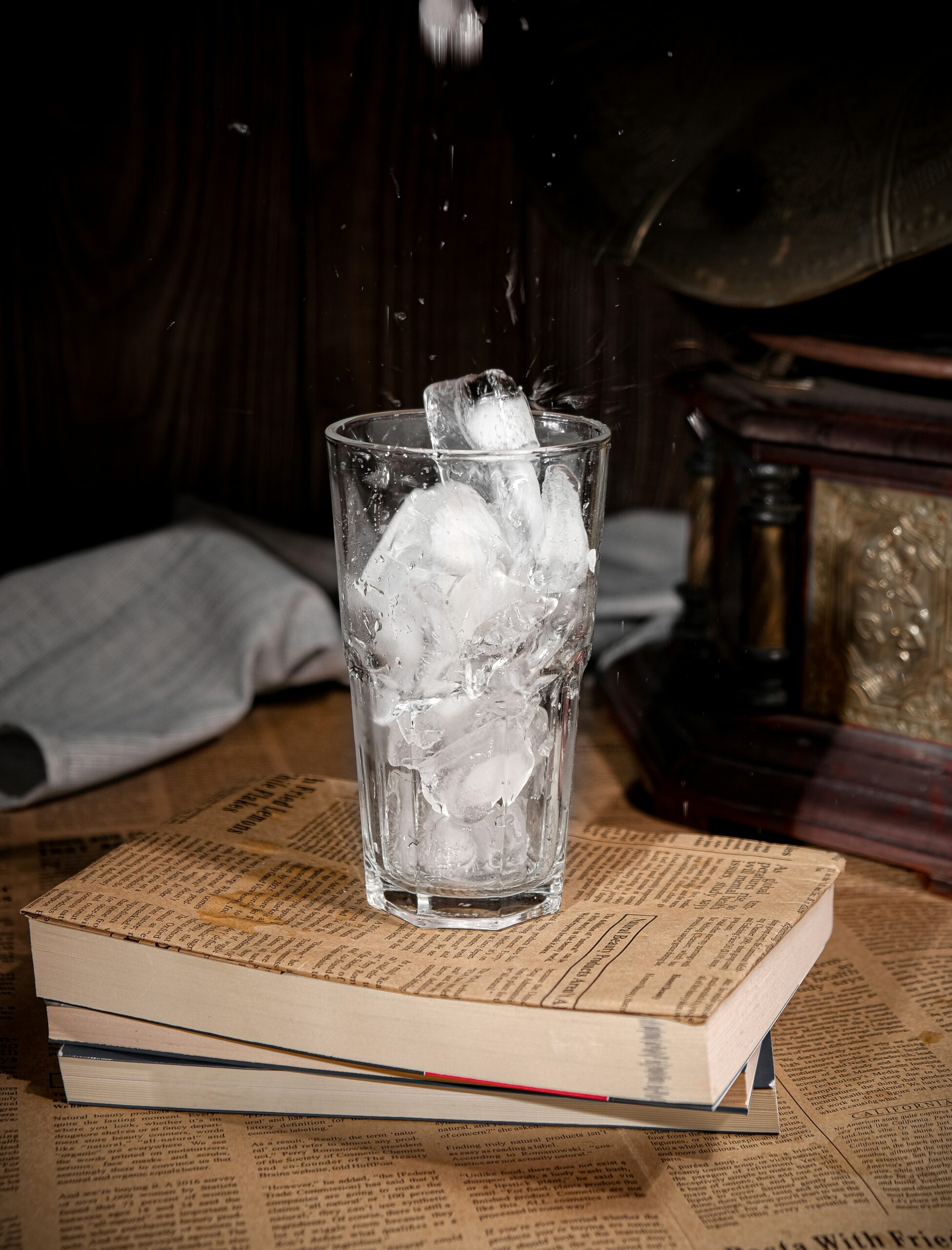

Whether it’s your commercial ice machine, walk-in cooler, or prep table, regular care ensures everything works when you need it most. Your equipment works hard every day, and without proper attention, it can fail at the worst possible moment.

Maintenance plans let you schedule routine checks and cleanings, so you avoid emergencies and protect your food and drinks. This is especially important during busy seasons when demand is high.

By investing in a maintenance plan tailored to your needs, you reduce energy use and extend the life of your machines. This helps you focus on serving your customers.

What Are Restaurant Equipment Maintenance Plans?

Restaurant equipment maintenance plans help you keep your kitchen appliances working well. They cover routine checks, cleaning, and repairs to stop problems before they start.

These plans save you time, money, and stress by making sure your equipment stays reliable and safe.

Definition and Purpose

A restaurant equipment maintenance plan is a service agreement that schedules regular inspections and upkeep for your kitchen tools. This includes appliances like walk-in coolers, ice machines, ovens, and prep tables.

The main goal is to catch small issues early and avoid unexpected breakdowns. It also helps keep your equipment clean and running efficiently.

With a plan, you know your business won’t be interrupted by sudden repairs. Maintenance plans also help extend the life of your equipment.

This keeps your kitchen ready for busy days and helps you meet food safety standards.

Types of Maintenance Plans

There are several types of maintenance plans, each designed to fit different needs and budgets. Common types include:

- Preventive Maintenance: Regular scheduled visits to inspect, clean, and tune appliances before problems occur.

- Corrective Maintenance: Repairs done when something breaks, usually without a schedule.

- Full-Service Plans: Combined preventive checks and all needed repairs included in one package.

You might also find custom plans that focus on specific equipment, like ice machines or walk-in coolers. Choose a plan that matches your kitchen’s size, equipment type, and how busy your business gets.

Importance in Food Service Operations

Maintenance plans are essential in food service because downtime can cause big losses. If your fridge or ice machine stops, food can spoil, and orders may be delayed.

This hurts your reputation and revenue. Regular maintenance helps prevent these problems.

It ensures equipment runs smoothly during rush hours and seasonal peaks, like summer in Memphis when ice demand is high. Clean and well-maintained machines also improve food safety by avoiding contamination risks.

By having a reliable maintenance plan, you reduce emergency repair costs and avoid the stress of equipment failure.

Key Components of an Effective Maintenance Plan

A good maintenance plan focuses on regular checks, clear task schedules, and careful record-keeping. These parts help you avoid unexpected breakdowns and keep your equipment running smoothly.

Staying organized ensures your kitchen can handle busy days without costly downtime.

Scheduled Inspections

Regular inspections catch small issues before they become big problems. You should set specific times to check your ice machines, refrigerators, ovens, and other key units.

Inspecting filters, seals, and electrical connections helps you spot wear and tear early. Keep a checklist that covers all equipment parts.

This includes checking for leaks, unusual noises, and proper temperature settings. For example, inspecting your walk-in cooler weekly during busy seasons can prevent spoilage.

A clear schedule means no equipment gets overlooked. You might schedule deeper inspections monthly and lighter ones weekly.

This routine prevents surprises that disrupt your operation.

Preventative Maintenance Tasks

Preventative tasks are the actions you take to keep machines running as they should. These include cleaning, lubricating parts, and changing filters on a regular basis.

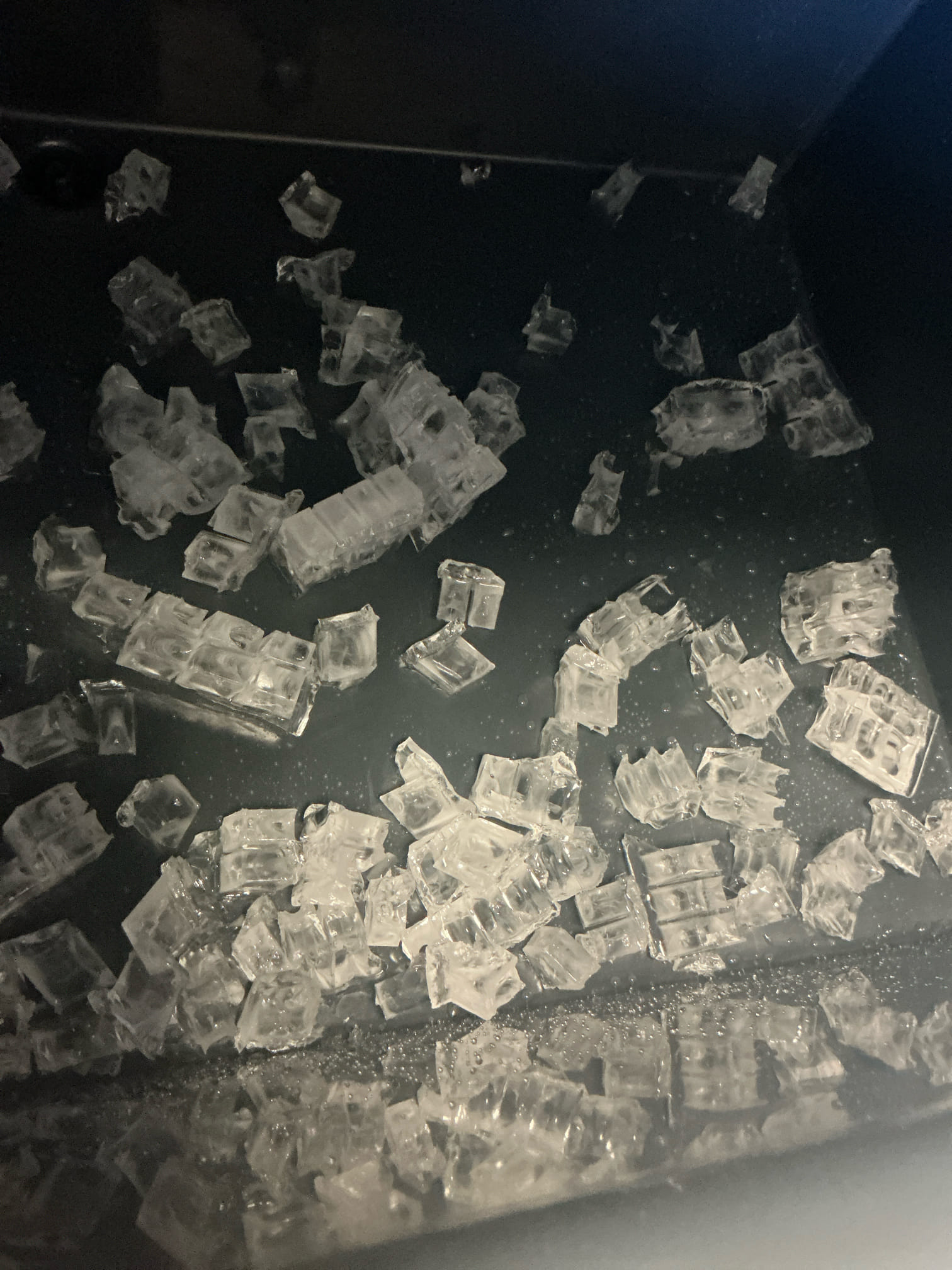

By performing these tasks on time, you reduce the risk of equipment failure. For instance, changing your ice machine’s water filter every three months helps maintain ice quality and equipment efficiency.

Cleaning condenser coils on refrigeration units keeps them cool and reduces energy use. Create a calendar listing tasks by equipment type and timing.

Assign clear responsibilities to your staff or service team. Routine preventative care means fewer emergency repairs and extends your equipment’s life.

Equipment Servicing Logs

Keeping detailed service logs strengthens your maintenance plan. These logs track inspections, repairs, and any parts replaced.

With clear records, you can see patterns in equipment performance and schedule future maintenance confidently. Use a simple log format that records the date, what was done, and who performed the work.

For example:

| Date | Equipment | Task Performed | Technician |

|---|---|---|---|

| 09/15/2025 | Walk-in Cooler | Filter replaced | Memphis Ice Team |

| 09/20/2025 | Ice Machine | Full cleaning | In-house staff |

Logs also help when working with service providers. They provide a history that speeds diagnosis and ensures the right parts get used.

Consistent record-keeping keeps your equipment in the best shape.

Benefits of Regular Restaurant Equipment Maintenance

Regular care for your restaurant equipment helps keep everything working like it should. You’ll avoid unexpected problems, save money on repairs, and get better use out of your machines.

Extended Equipment Lifespan

When you maintain your kitchen equipment regularly, it lasts longer. Small issues, like worn parts or buildup inside machines, get fixed before they become major problems.

This means you don’t have to replace things as often. For example, cleaning ice machines stops mold and slime from damaging parts.

Serving clean ice also means your customers get better quality. Walk-in cooler repair done early keeps your refrigeration efficient and avoids costly breakdowns.

You protect your investment by sticking to a maintenance plan. Over time, this approach saves you money.

Improved Kitchen Efficiency

Well-maintained equipment runs faster and uses less energy. When your refrigerator, ice machines, and prep tables work at their best, you spend less time fixing issues during busy hours.

A clean ice machine produces clear ice quickly, and a cooler holds temperature well. These improvements keep your staff moving and help you serve customers with no delays.

Clean machines reduce chances of bacteria or mold, keeping your products safe. That supports your quality standards and local health codes.

Reduced Emergency Repairs

Regular maintenance helps catch small problems before they turn into big emergencies. You avoid costly last-minute repairs that disrupt your service.

With scheduled checkups, you’re less likely to have machines break down during peak business times. This means fewer calls for urgent fixes and less downtime in your kitchen.

A maintenance plan gives you peace of mind. You can plan ahead, knowing experts will keep your equipment in shape.

How to Choose the Right Maintenance Plan for Your Restaurant

Choosing the right maintenance plan means matching services to your equipment’s condition and your business needs. You need clear information about your equipment, reliable service providers, and a plan tailored to your schedule and budget.

This helps you avoid breakdowns and keeps your kitchen running smoothly.

Assessing Your Equipment Needs

Start by making a list of all your key equipment. Include commercial ice machines, walk-in coolers, prep tables, and refrigeration units.

Note their age, brand, and any past issues. Think about the daily workload and how critical each piece is to your operation.

Older machines may need more frequent checks. Newer equipment might still need regular cleaning but fewer repairs.

Don’t overlook special features like energy-saving modes or unique parts. These details help identify what kind of maintenance makes sense.

Documenting this helps you explain your needs clearly when talking with service providers.

Comparing Service Providers

Look for providers with experience in your restaurant type and region. A local company like Memphis Ice understands Mid-South climate challenges, which affect your equipment’s lifespan.

Check what services they include: cleaning, inspection, repairs, and emergency calls. Also, ask about their visit frequency options—monthly, quarterly, or customized schedules.

Request references or customer reviews to gauge reliability. See if they have technicians trained on your specific brands.

Pricing should be transparent, with no hidden fees. Write down key points from each provider to compare side by side.

Customizing Your Plan

A good maintenance plan fits your restaurant’s busy times and equipment demands. If summers are your peak season, schedule more visits before and during these months.

Plans can include:

- Regular compressor and filter checks

- Deep cleaning schedules

- Priority repair services

Some providers offer flexible plans that adjust as your needs change. Make sure the plan includes clear communication about what’s covered and how to request extra service.

Customization helps reduce unexpected downtime and keeps costs predictable. Work with your provider to tweak the plan until it feels right for your daily operations.

Common Maintenance Tasks for Commercial Kitchen Equipment

Keeping your kitchen equipment in top shape means regular cleaning, fine-tuning, and replacing worn parts. These steps help prevent breakdowns and keep your kitchen running smoothly.

Cleaning Procedures

Cleaning is your first line of defense against equipment failure and food safety issues. Focus on daily wiping of handles, shelves, and ice makers.

This keeps bacteria and grime from building up. Schedule deeper cleanings weekly or monthly for parts like condensers, fans, and drip trays.

Always use approved cleaning products to protect surfaces and avoid damage. Pay special attention to prep tables, refrigerators, and ice machines.

A clean workspace supports quick food assembly and safe storage.

Calibration and Adjustments

Equipment like refrigerators and ovens need regular calibration to stay accurate. Check temperature settings weekly with a reliable thermometer.

If you notice your walk-in cooler isn’t holding the right temperature, adjust the thermostat and test it again. Proper calibration prevents food spoilage and wasted energy.

Check seals and door alignment too. A tight seal keeps cold air inside and reduces wear.

Replacement of Wearable Parts

Wearable parts need timely replacement to keep your equipment running efficiently. Filters, gaskets, and belts often show signs of wear after months of use.

Inspect parts every few months and swap them out before they fail. For ice machines, regularly replace water filters and clean ice bins.

Keeping up with these small fixes prevents larger breakdowns and costly repairs. It also helps your equipment work at peak performance.

Cost Considerations for Maintenance Plans

When planning maintenance for your restaurant equipment, understanding how costs break down helps you make smart decisions. You’ll want to know how pricing works, how to fit maintenance into your budget, and how these choices save money over time.

Pricing Models

Maintenance plans often use a few common pricing models. Some charge a flat monthly or yearly fee, which covers routine inspections and small repairs.

Others bill based on the services you actually need, like fixing a broken ice machine or replacing parts. Flat fees give you steady costs and prevent surprise bills.

Pay-as-you-go plans might save money upfront but could add up if you face frequent repairs. Some plans offer tiered pricing, where basic coverage costs less but full coverage is more expensive.

Knowing these options helps you pick a plan that fits your business size and equipment use. Always ask what’s included to avoid hidden fees.

Budgeting for Maintenance

Set aside dedicated money for equipment upkeep to avoid emergency expenses. Many restaurant owners budget about 5-10% of their equipment’s value annually for maintenance.

Break your budget down by equipment type, like refrigeration, ice machines, and cooking gear. For example, ice machines need regular cleaning and checks to prevent costly breakdowns, so factor that into your yearly costs.

Consider seasonal changes too. More use during summer means more wear.

Balance your budget to cover peak and slow periods without strain.

Long-Term Savings

Investing in a maintenance plan lowers your overall costs. Regular care extends equipment life and reduces the need for big repairs.

Routine ice machine maintenance keeps it efficient and helps you avoid costly replacements. Preventing breakdowns also means your business won’t lose sales due to downtime.

This reliability saves money and stress. Think of maintenance as protection for your investment.

Signs Your Restaurant Equipment Needs Maintenance

Your equipment shows clear warnings when it needs maintenance. Watch its performance, check its parts, and monitor energy use to save on repairs and downtime.

Performance Issues

If your equipment starts working slower or less efficiently, something is wrong. For example, an ice machine that takes longer to make ice or a walk-in cooler that struggles with temperature needs attention.

Strange noises like grinding or hissing can point to mechanical problems or blocked parts. Ice machines that produce ice with odd tastes or smells often have buildup or contamination inside.

When you notice inconsistent performance, act quickly. Catching small issues early helps avoid major breakdowns.

Visible Wear and Tear

Look closely at your equipment daily. Cracked seals, rust, or worn gaskets on refrigerators or prep tables signal it’s time for a check-up.

Mold or slime inside ice bins is a red flag for poor maintenance and risks health code violations. Filters clogged with dirt and water lines with mineral deposits affect both safety and operation.

Fix small cracks or loose parts quickly before they cause more damage. Regular inspection keeps your equipment safe and reliable.

Unexpected Energy Usage

A sudden spike in energy bills often means your machines are working harder than they should. Refrigeration units with clogged condenser coils or failing compressors use more electricity to maintain temperature.

Increased energy use raises costs and puts strain on equipment parts, which can shorten their lifespan. If your latest bills surprise you, have a technician review your system.

Fixing energy drains improves efficiency and protects your investment.

DIY Maintenance vs. Professional Services

Managing your restaurant equipment means knowing which tasks you can do yourself and when to call experts. Finding the right balance helps you avoid breakdowns and keeps your kitchen running.

Pros and Cons of DIY

Doing maintenance yourself can save money and help you spot problems early. Simple tasks like cleaning prep tables or wiping down ice machines prevent dust and grime build-up.

You can act quickly without waiting for a technician. However, DIY comes with risks.

You might miss hidden issues or damage parts without proper training. Complex repairs require special tools and knowledge.

If you skip professional checks, you could face bigger, unexpected costs later.

Pros of DIY:

- Saves money on small tasks

- Immediate action when problems appear

- Basic cleaning extends equipment life

Cons of DIY:

- Risk of missing hidden problems

- May cause accidental damage

- Doesn’t replace expert inspection

When to Call a Professional

Call a professional if you notice unusual noises, poor performance, or if your equipment can’t keep proper temperatures. Professionals handle deep cleaning, system diagnostics, and part replacement to keep your machines in line with health and safety rules.

Professional service is especially important for complex equipment like commercial ice machines or walk-in coolers. These machines have many parts that need precise care.

Schedule expert maintenance before busy times to reduce the risk of breakdowns. Watch for leaks, strange smells, or inconsistent cooling and get help fast.

Staff Training for Basic Care

Training your staff on basic equipment care saves you time and money. Teach them how to clean surfaces, check for damage, and report issues early.

Staff should know proper cleaning methods and how often to do them. Wiping down prep tables daily and clearing ice machine filters regularly helps avoid bigger problems.

Routine checks reduce equipment wear. Trained staff ensure small problems don’t get ignored.

Clear instructions and regular refreshers keep everyone on the same page. This makes maintenance easier for you.

Implementing a Maintenance Plan in Your Restaurant

A solid plan helps your restaurant keep equipment running smoothly and avoid costly breakdowns. Clear roles, detailed tracking, and scheduled tasks make the process easier.

Staff Roles and Responsibilities

Assign clear roles to your team. Decide who will handle daily cleaning, who will watch for problems, and who coordinates with technicians.

Kitchen staff can clean equipment surfaces and check for leaks. Supervisors should monitor performance and report issues early.

Train everyone on basic maintenance tasks like cleaning ice bins, checking filters, and spotting mold or slime. Write down all roles and make sure everyone understands them.

Tracking Progress

Track maintenance to stay on top of tasks and spot trends. Use a log or digital system to record when equipment is cleaned, inspected, or repaired.

Include notes on any issues you find. Create a checklist with key points like filter changes, mechanical tests, and coil cleaning.

Review records regularly to plan repairs before machines fail. Good records help you prove maintenance was done if needed.

Setting Maintenance Schedules

Set maintenance twice a year for most commercial equipment, like ice machines and coolers. If your machines work harder during summer, add a spring checkup before busy season.

Build your schedule around your restaurant’s busy and slow times. Plan deep cleanings and technical checks during slower periods to avoid interruptions.

Use calendar reminders or software alerts to keep tasks on track.

Here’s a simple example schedule:

| Equipment | Task | Frequency |

|---|---|---|

| Ice machine | Clean & test parts | Every 6 months |

| Walk-in cooler | Inspect seals & coils | Twice a year |

| Prep tables | Daily surface wipe | Daily |

This structure helps you avoid surprises and keeps equipment safe.

Staying Compliant with Health and Safety Regulations

Well-maintained equipment helps you meet rules and protect your customers. It involves passing local inspections and following food safety laws.

Regular care for ice machines and refrigeration makes compliance easier and keeps your business running.

Meeting Local Inspection Requirements

Local health inspectors check equipment temperature, cleanliness, and condition. Keep accurate temperature logs for coolers, freezers, and ice machines every day.

This proves you follow local health department rules. Regular maintenance helps catch problems before inspections.

Servicing your walk-in cooler or ice machine prevents breakdowns and keeps temperatures steady. Clean equipment shows inspectors you take safety seriously.

A maintenance plan with detailed records makes inspections less stressful. When repairs or replacements are needed, you can plan ahead to avoid rushing.

Ensuring Food Safety Standards

Your ice machine and refrigeration units must keep food at safe temperatures to prevent spoilage and bacteria growth. Using filtered water in your ice machine improves ice quality and reduces contamination risk.

Cleaning schedules are key. Dirty machines or coolers can spread germs.

Clean and sanitize your equipment based on manufacturer recommendations and local health guidelines. Reliable service contracts help maintain this routine.

Technicians can replace filters, check seals, and verify temperatures regularly. When your equipment works right, you protect your customers and meet food safety rules.

Future Trends in Restaurant Equipment Maintenance Plans

Maintenance plans are changing to help you save money and improve equipment performance. New tools and approaches focus on smarter monitoring and greener practices.

These changes make keeping your restaurant running easier and more cost-efficient.

Smart Technology Integration

Expect more equipment with smart sensors and automation. These devices track temperature, running hours, and part wear in real time.

They send alerts when something needs attention, so you can book repairs before a breakdown. Smart systems let you monitor multiple machines remotely.

This means less downtime and better energy management. For example, a walk-in cooler might adjust its cooling based on outside temperature to save power.

Using smart tech helps you plan maintenance more accurately. Instead of fixed schedules, you get service when it’s needed most.

This reduces costs and extends the life of your equipment.

Eco-Friendly Maintenance Solutions

More restaurants want to lower their environmental impact through maintenance. Eco-friendly cleaning products and biodegradable lubricants protect your equipment and the planet.

Routine checks can also focus on energy efficiency. Fixing leaks, cleaning coils, and replacing worn parts cuts down energy waste.

Some maintenance plans include seasonal tune-ups that improve system efficiency during peak times. Switching to greener refrigerants is another growing trend.

These new refrigerants have less impact on climate change and help keep your equipment compliant with regulations. Choosing a maintenance plan with eco-friendly features supports your business goals and shows care for your community.

Frequently Asked Questions

Keeping your restaurant equipment running smoothly depends on smart priorities, regular checks, and good planning. The right schedule and support help you avoid breakdowns and keep your kitchen working.

What items should be prioritized in a restaurant equipment maintenance plan?

Focus first on equipment used daily and those that affect food safety. This includes refrigeration units, ice machines, ovens, fryers, and prep tables.

These items need regular checks to avoid failures that stop your kitchen.

How often should I schedule preventive maintenance for my commercial kitchen equipment?

Preventive maintenance varies by equipment type but usually happens every 3 to 6 months. Ice machines and refrigeration often need more frequent servicing because they run non-stop.

Other equipment may need quarterly or biannual inspections to stay in top shape.

Can you recommend a template for a restaurant maintenance checklist?

A good checklist covers daily, weekly, and monthly tasks. Include cleaning filters, checking temperatures, inspecting seals, and testing controls.

Note any repairs and set reminders for service dates to keep everything on track.

What are the benefits of having a dedicated maintenance plan for small restaurant equipment?

A dedicated plan means fewer surprises and longer equipment life. You save money by avoiding repairs and downtime.

It also helps you keep the kitchen safe and running efficiently so you can focus on serving your customers.

How can I create an effective equipment maintenance plan for my restaurant?

List all equipment and learn each item’s maintenance needs. Set a realistic schedule for inspections, cleaning, and repairs.

Keep clear records of all work done. Train your team on basic upkeep so issues get spotted early.

What considerations are important when choosing a restaurant equipment maintenance company?

Choose a company with experience in commercial kitchens. Local knowledge of the Mid-South is also important.

The company should offer both emergency repairs and regular maintenance. Make sure they provide full-service support.

Look for reliable communication. Honest pricing helps create a stress-free partnership.

Recent News

Tips for Extending Lifespan of Walk-In Cooler Doors Friendly Maintenance and Care Guide

Tips for Extending the Life of Commercial Refrigeration Units with Easy Maintenance Habits

Emergency Walk-In Freezer Repair Tips to Keep Your Business Running Smoothly

Emergency Cold Storage Solutions for Events Made Easy and Reliable

Common Reasons Ice Machines Run Loud and How to Fix Them Easily

Common Ice Machine User Mistakes and How to Prevent Them for Smooth Operation