proudly serving

the mid-south

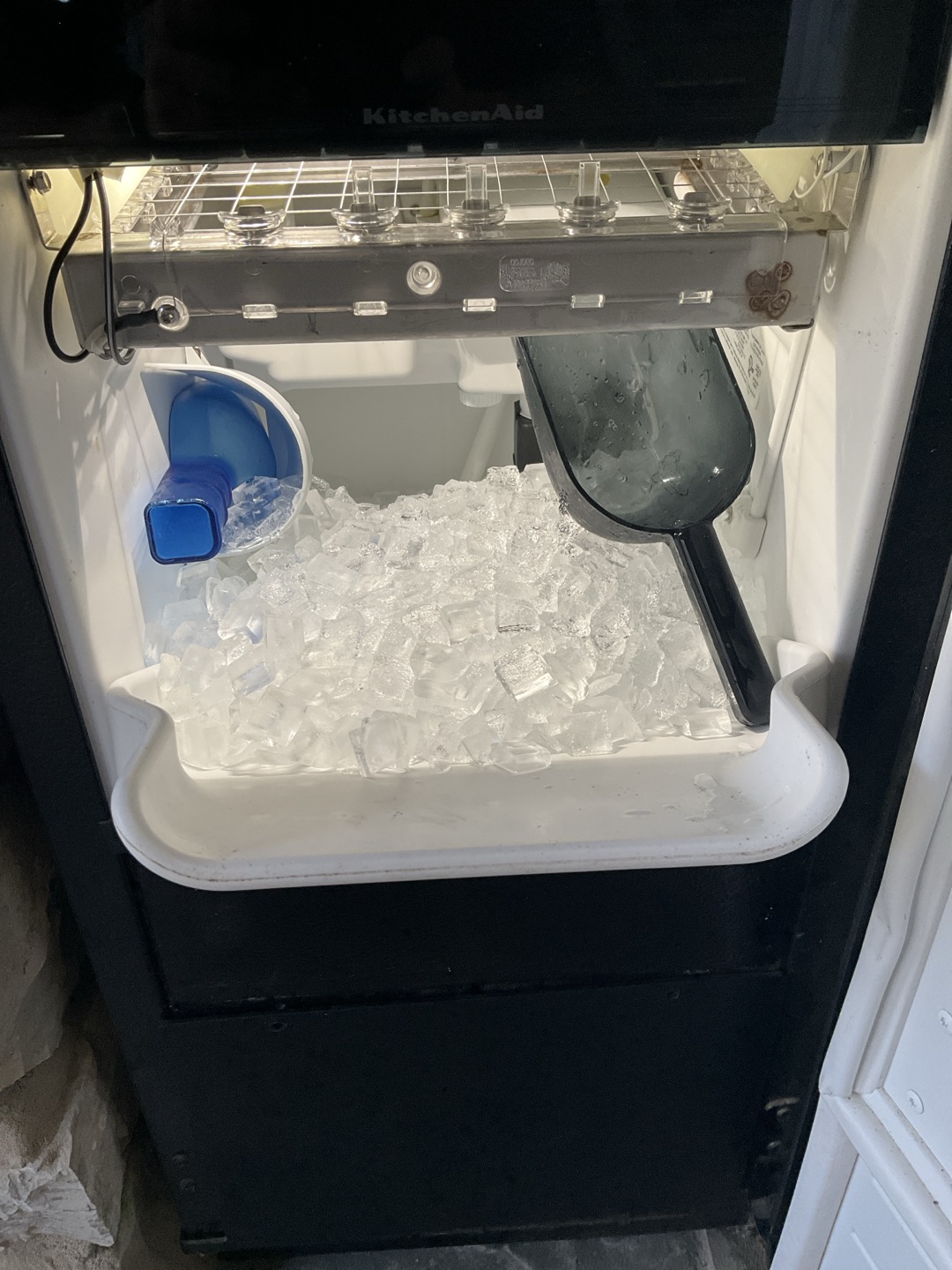

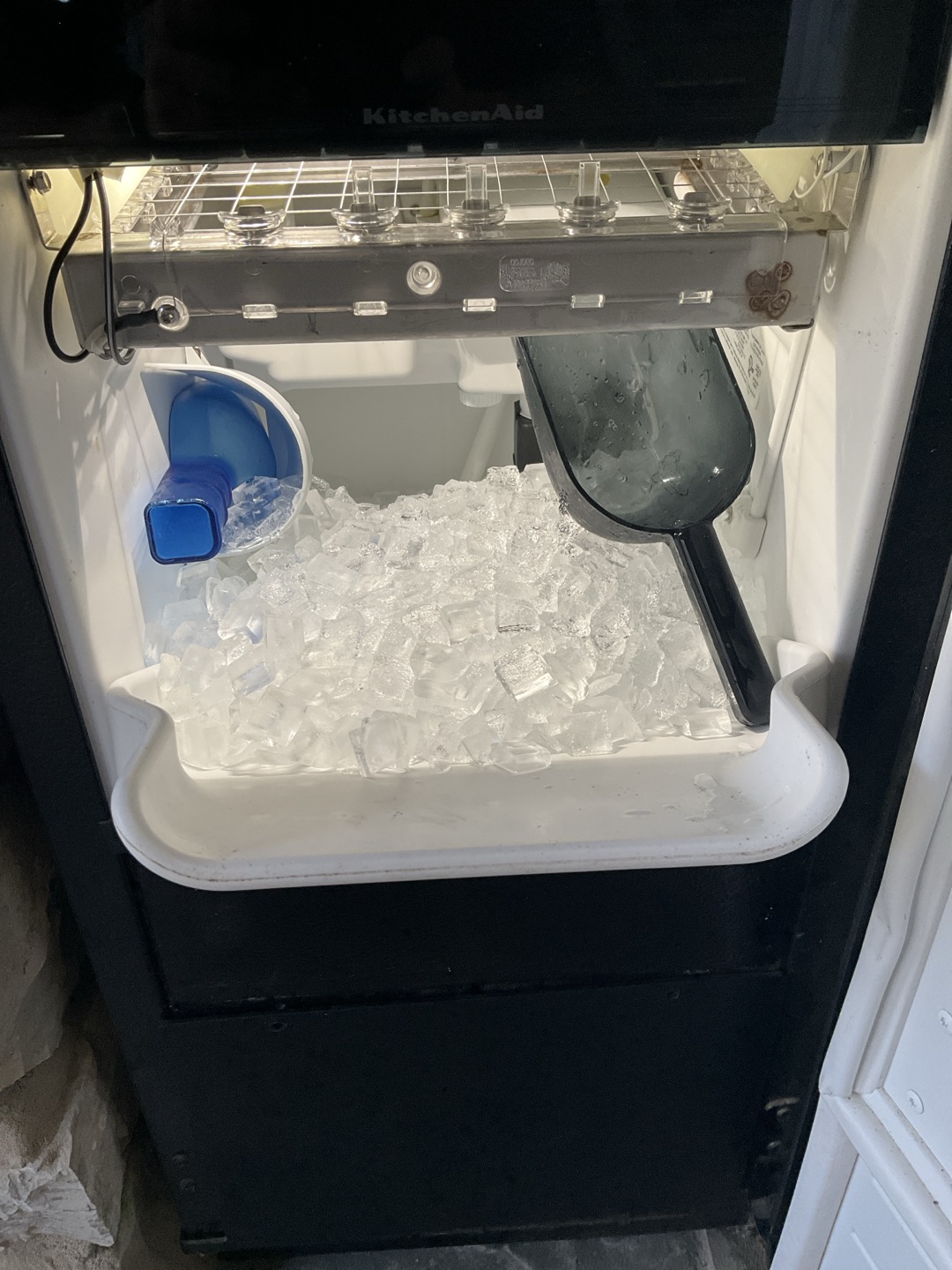

Emergency Ice Machine Repair Service for Fast, Reliable Solutions

When your ice machine breaks down unexpectedly, it can disrupt your entire operation. Emergency ice machine repair service is designed to get your equipment back up and running quickly, minimizing downtime and keeping your business cool even during the busiest hours. Whether you run a restaurant, bar, or healthcare facility, prompt and reliable repair is essential to avoid costly delays.

At Memphis Ice, we understand the urgency of malfunctioning ice machines in the Mid-South’s heat. You can count on a trusted local team with decades of experience to diagnose and fix issues efficiently, so your workflow isn’t compromised. Fast response and expert care mean you won’t have to worry about last-minute ice shortages or emergency runs to stores.

Planning ahead by knowing who to call for emergency repairs gives you peace of mind. From walk-in cooler repairs to commercial ice machine service, Memphis Ice has supported regional businesses for nearly 50 years—helping you focus on what matters most.

Understanding Emergency Ice Machine Repair Service

When your ice machine stops working unexpectedly, quick action is crucial to avoid disruptions. Recognizing what makes a repair urgent helps you decide when to call for immediate help. Common emergency situations and how they differ from routine service clarify when fast intervention is necessary.

What Qualifies as an Emergency

An emergency ice machine repair occurs when downtime directly impacts your business operations or health standards. For example, if your commercial ice maker suddenly stops producing ice in the middle of service hours, it threatens customer satisfaction and compliance.

Some clear signs include:

- Complete ice production failure

- Leaking water causing safety hazards

- Malfunctions that risk contaminating stored ice

- Electrical issues creating fire risks

If any of these happen, you need a repair service ready to respond immediately, minimizing costly downtime. Memphis Ice understands these priorities and offers responsive emergency ice machine repair to keep your operation running smoothly.

Typical Scenarios That Require Immediate Service

Emergency repairs often arise from sudden breakdowns during peak business times. Common scenarios include:

- Ice maker motor failures during busy shifts

- Cooling system malfunctions in hot weather causing overheating

- Water supply interruptions leading to inconsistent ice production

- Blocked drainage causing flooding in kitchen or bar areas

These situations require a fast diagnosis and repair to restore ice availability quickly. Delaying could reduce your ability to meet service demands or impact food safety. Regular ice machine maintenance can help prevent many emergencies, but when they do occur, Memphis Ice provides timely support tailored to your needs.

Differences Between Emergency and Regular Repair

Emergency ice machine repair focuses on speed and restoring basic function to prevent interruptions. The goal is to get your machine operational again as soon as possible, even if temporary fixes are needed initially. Regular ice machine service, in contrast, is planned and routine, addressing minor issues, cleaning, and preventive maintenance to extend equipment lifespan.

Key differences include:

| Aspect | Emergency Repair | Regular Service |

|---|---|---|

| Response Time | Immediate or within hours | Scheduled appointments |

| Nature of Work | Urgent fixes to restore function | Routine maintenance and updates |

| Impact on Operations | High urgency to minimize downtime | No immediate interruption |

| Cost | Typically higher due to priority | Usually lower, planned expenses |

Understanding these distinctions helps you determine when to contact Memphis Ice for emergency ice machine repair versus scheduling regular service visits.

Common Ice Machine Problems Requiring Fast Repairs

When your ice machine fails, it’s often clear which problem needs immediate attention. Issues with production, water supply, or unusual noises can disrupt your operation quickly and require prompt, professional ice machine repair to avoid downtime.

Breakdowns and Failure to Produce Ice

An ice machine that stops making ice or produces very little is a critical concern. This issue often stems from compressor failure, thermostat malfunction, or a blocked condenser coil. Without ice, your business could face customer dissatisfaction or operational delays.

Checking the power supply and reset options may help initially, but prolonged stops usually need professional repair to diagnose mechanical or electrical faults. A quick response can protect your equipment from further damage and keeps your business running smoothly.

Water Line and Filter Issues

Water supply problems prevent your ice machine from producing clean, adequate ice. A clogged filter or kinked water line can reduce flow, causing slow ice production or machine shutdown. Leaks in these components risk water damage and increase repair costs if ignored.

Ensure your water filters are replaced regularly and supply lines are checked while scheduling professional maintenance. Experienced technicians, like those at Memphis Ice, identify issues early and restore proper water flow before bigger problems arise.

Unusual Sounds and Leaks

Listen for loud humming, buzzing, or grinding noises—they often signal motor or fan problems. Continuous noise can indicate worn bearings or ice jams inside the machine. Ignoring these sounds may lead to complete equipment failure.

Leaking water is another sign of trouble, typically from clogged drains, broken seals, or faulty valves. Addressing leaks immediately prevents unsanitary conditions and damage to surrounding equipment. For trusted, timely repairs in the Mid-South, rely on professionals who understand the urgency of these issues.

Steps in Emergency Ice Machine Repair

When your ice machine stops working, quick and precise action is needed to limit downtime. The process begins with thorough troubleshooting to identify the cause. Then, effective onsite repairs or parts replacement restore functionality. Finally, you verify that the system operates properly before resuming full service.

Initial Troubleshooting and Diagnosis

Start by checking the power supply. Ensure your machine is plugged in and the circuit breaker hasn’t tripped. Next, confirm the water supply is connected and flowing properly, as water issues commonly cause ice production to fail.

Look for error codes or unusual noises in the machine. These clues help pinpoint problems like frozen components, faulty sensors, or clogged water filters. Avoid guessing; a methodical approach prevents unnecessary repairs.

Record what you find, noting any irregularities. If you’re comfortable, reset the system and observe if the issue remains. This phase sets the foundation for an effective repair by understanding exactly what’s wrong.

Parts Replacement and Onsite Fixes

Once diagnosed, replace or repair defective parts promptly. Common replacements include water filters, pumps, sensors, or ice molds. Use quality parts matched to your model to ensure reliability and avoid recurring breakdowns.

Some repairs, like clearing ice jams or cleaning condensers, can be done onsite. Thorough cleaning improves airflow and prevents overheating. Tighten loose connections and test all electrical components to confirm they function correctly.

Keep in mind, a trusted emergency ice machine repair service can expedite this step. At Memphis Ice, we’ve been keeping commercial ice machines working smoothly since 1977, ensuring your ice production gets back on track fast.

Final System Checks

After repairs, run a full system check before returning the ice machine to regular use. Monitor ice production rates and quality to confirm the problem is resolved. Check for leaks, unusual sounds, or temperature inconsistencies.

Verify automatic cycles complete without error and water drains correctly. This step ensures your machine operates safely and efficiently, reducing the risk of another emergency.

Document all work performed and share recommendations for future maintenance. This clarity helps prevent repeat calls and prolongs your equipment’s lifespan through planned care. For expert guidance, contact Memphis Ice, your trusted Memphis refrigeration experts.

Choosing the Right Emergency Ice Machine Repair Service

When your ice machine breaks down unexpectedly, choosing the right repair service quickly and decisively can prevent costly downtime. Focus on service providers who combine speed, proven expertise, and trusted credentials to minimize disruption to your business.

Qualities to Look For in Service Providers

You need a repair company that offers reliable communication, responds promptly, and provides clear pricing upfront. Look for technicians who are experienced with a wide range of commercial ice machines and can diagnose issues accurately on the first visit.

Additional qualities include:

- Availability of emergency repair services 24/7

- Use of high-quality replacement parts

- Transparent warranty on repairs for peace of mind

A company like Memphis Ice understands these needs and provides thorough service that ensures your machine is restored swiftly and correctly, supporting your operations in Memphis and the Mid-South region.

Importance of Speed and Availability

Emergency repairs demand immediate action to avoid interrupting your business flow. When ice supply is critical—such as in restaurants, hospitals, or bars—every minute without ice counts.

Choose a service provider that guarantees:

- Rapid response times, often the same day

- Flexible scheduling to accommodate your business hours

- 24-hour emergency availability to handle unexpected breakdowns

Quick and reliable service helps you avoid lost sales, customer dissatisfaction, or compromised safety standards. Memphis Ice prioritizes fast service calls within a 120+ mile radius, so your ice machine downtime remains as brief as possible.

Certifications and Experience

Experience alone isn’t enough; professional certifications add an essential layer of confidence in the service quality. Look for technicians certified by recognized industry organizations who stay current with the latest refrigeration and ice machine technologies.

Certified technicians offer:

- Up-to-date knowledge on diverse commercial ice machine brands and models

- Adherence to safety and environmental standards

- Technical skills to handle complex repairs and preventive maintenance

Memphis Ice’s long-standing reputation is built on nearly five decades of expertise and certified technicians who keep your equipment running safely and efficiently. This combination safeguards your investment and reduces repeat breakdowns.

Preventative Maintenance to Reduce Emergency Breakdowns

Keeping your ice machine running smoothly depends on routine care that avoids costly downtime. Addressing cleaning, professional service agreements, and operator habits are critical factors in minimizing unexpected breakdowns. Each step helps maintain reliability and extends the equipment’s life.

Regular Cleaning and Inspections

Daily and weekly cleaning prevents buildup that can impair ice quality and damage components. You should remove scale, mineral deposits, and biofilm from water lines, dispensers, and storage bins according to manufacturer guidelines. Checking for leaks, worn seals, or unusual noises can help spot problems early.

A typical cleaning schedule includes:

- Daily: Wipe down exterior surfaces and drain trays.

- Weekly: Clean water filters and spray nozzles.

- Monthly: Perform sanitizing cycles and inspect condenser coils.

Neglecting these tasks can cause unexpected breakdowns and reduce efficiency. Regular inspections help you avoid emergency ice machine repair service by catching minor issues before they escalate.

Maintenance Contracts

Enrolling in a maintenance contract ensures your ice machine receives expert care at scheduled intervals. These agreements often include thorough system diagnostics, cleaning beyond daily capabilities, and parts replacement as needed. Contracts can be tailored to your machine’s usage, typically scheduling service every 3 to 6 months.

Having a consistent service plan means quicker response times and priority scheduling when repairs become necessary. It also lowers the risk of prolonged downtime during peak business periods. Memphis Ice offers maintenance programs designed to fit your operation’s needs and reduce costly emergency repairs.

Best Practices for Operators

Operators play a crucial role in preventing malfunctions. Training your staff on daily ice machine care helps maintain proper function between professional service visits. Simple practices include:

- Monitoring ice production rates for dips or irregularities.

- Ensuring proper water supply and temperature settings.

- Promptly reporting unusual sounds or leaks.

Documenting maintenance routines and communicating issues early can save you significant repair costs. Your team should understand that their proactive attention is key to keeping the machine reliable and your business running smoothly.

Frequently Asked Questions

You need quick, clear answers to keep your ice machine running without costly downtime. Knowing who to contact, typical repair times, and cost considerations helps you act fast. Understanding common issues and preventive care keeps you one step ahead.

Who do I contact for immediate repairs when my ice machine stops working?

You should reach out to a reliable local service with certified technicians experienced in commercial ice machines. Memphis Ice offers prompt, professional emergency repair to get your operation back on track quickly.

What is the standard timeframe for an ice machine’s emergency repair service?

Emergency repairs typically take a few hours to a day, depending on the severity of the issue and parts availability. Fast response times are critical, especially during busy periods like summer, to minimize lost ice production.

How can I determine if it’s more cost-effective to repair or replace a malfunctioning ice maker?

Consider the age of your machine and the repair cost relative to replacement. If repairs approach half the cost of a new unit or there are frequent breakdowns, replacement might save money in the long run.

What are some common issues that ice machine repair services can fix on an emergency basis?

Technicians often address problems like compressor failure, clogged water lines, faulty thermostats, or ice buildup. These issues commonly cause your ice machine to stop making ice or freeze up, jeopardizing your operation.

Are there certified technicians who specialize in commercial ice machine repairs?

Yes, certified technicians with specialization in commercial ice machines ensure proper diagnosis and repair. Memphis Ice’s team is trained to handle a variety of commercial brands and models with efficiency and care.

What preventive maintenance steps can avoid the need for emergency ice maker repairs?

Regular cleaning, timely filter replacement, and scheduled tune-ups prevent buildup and mechanical wear. Following a maintenance plan designed for your environment reduces unexpected breakdowns and keeps ice flowing steadily.

Recent News

Best Practices for Storing Food Around Ice Bins Safely and Efficiently

Best Practices for Loading and Unloading Walk-In Freezers Made Easy and Efficient

Best Practices for Cleaning Walk-In Cooler Shelving Tips for Maintaining Hygiene and Efficiency

Best Practices for Cleaning and Sanitizing Commercial Ice Equipment to Keep It Safe and Sparkling

Best Maintenance Tips for Bar Refrigeration Systems to Keep Your Drinks Cold and Equipment Running Smoothly

Benefits of Working with Certified Refrigeration Technicians for Reliable and Efficient Cooling Solutions