proudly serving

the mid-south

Commercial Ice Machine Repair Memphis Tips for Fast, Reliable Service

When your commercial ice machine in Memphis stops working, it can put your whole business on hold. Getting fast, reliable repair from a local expert ensures your ice supply stays steady and your customers stay happy.

Whether you run a restaurant, hospital, or retail store, you need a partner who understands how important ice is for your day-to-day operations. You want a team that knows the Mid-South climate and the challenges businesses face here.

With nearly 50 years of experience, Memphis Ice Machine Company offers quick repairs, regular maintenance, and trusted service. Our service keeps your equipment running smoothly all year.

You don’t have to worry about surprise breakdowns. We handle the cold so you can focus on your business.

Commercial Ice Machine Repair Services in Memphis

Keeping your commercial ice machine working right means faster repairs and less downtime. You need service that covers different types of machines and common problems.

Knowing what to expect helps you plan and make sure your ice supply never stops.

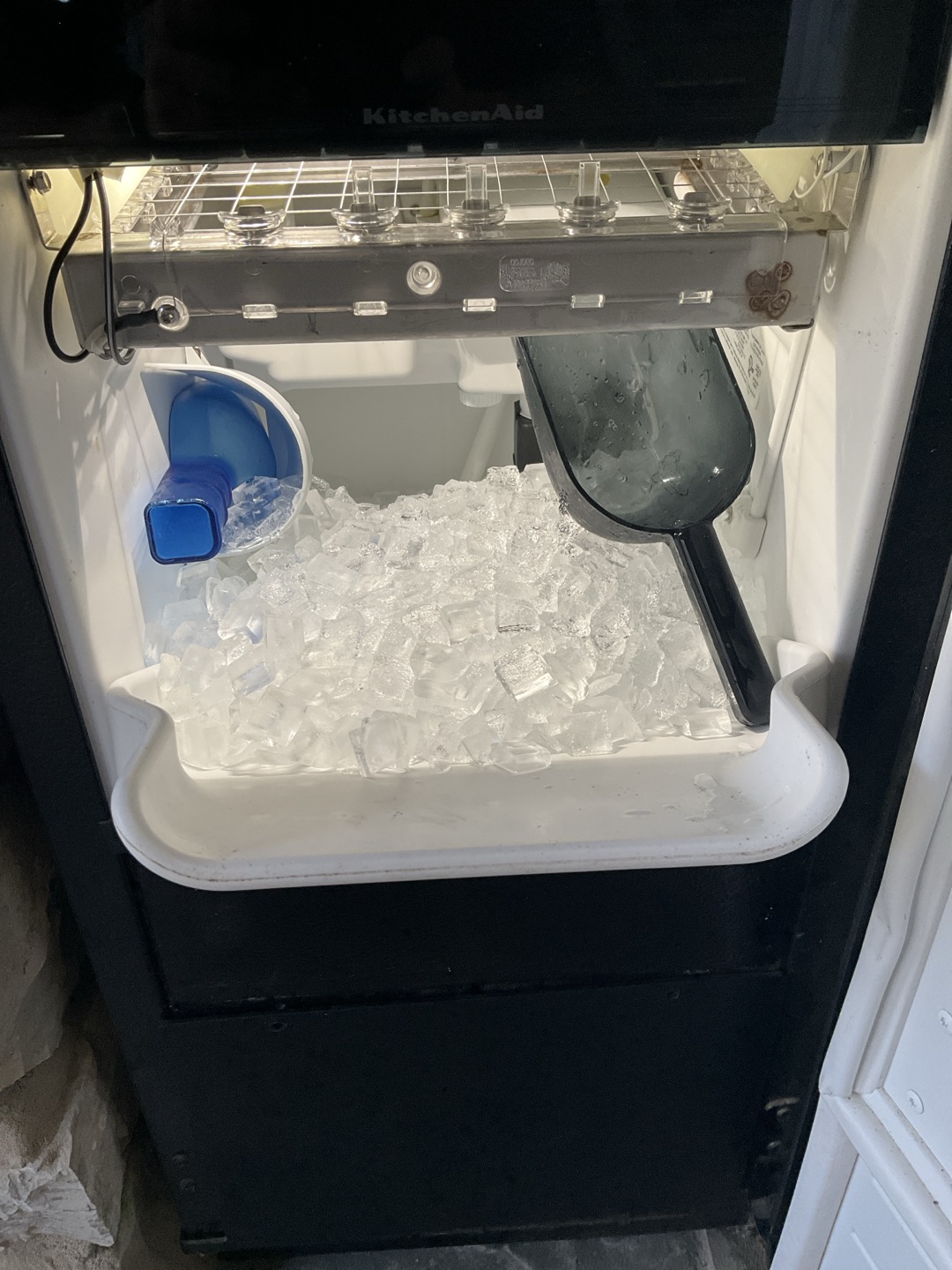

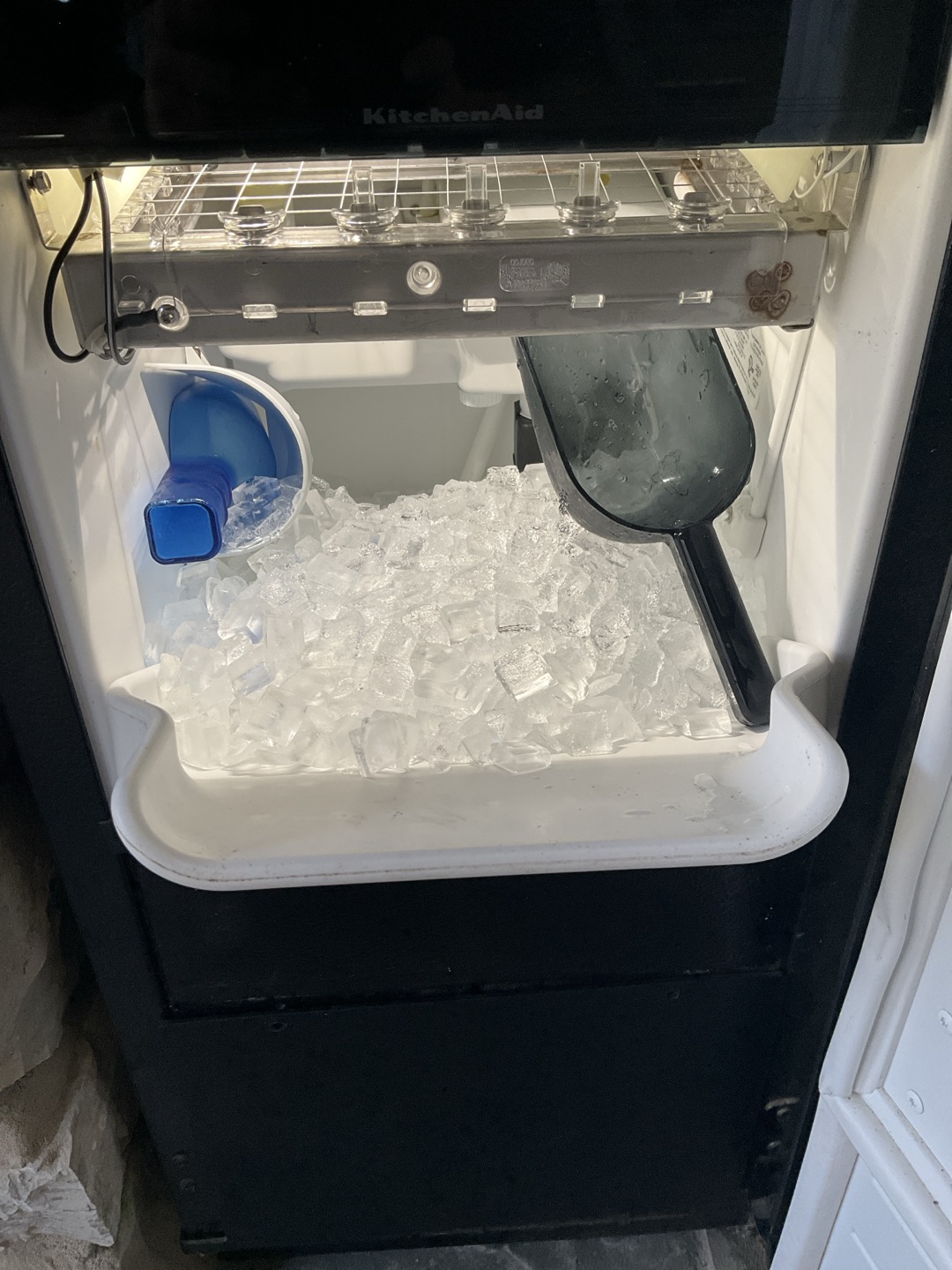

Types of Ice Machines Serviced

You’ll find many kinds of ice machines in Memphis businesses. We service:

- Undercounter machines: Small, space-saving units often used at bars or in small kitchens.

- Modular machines: Larger, standalone units that produce more ice for busy restaurants and hospitals.

- Countertop models: Compact and portable machines for retail or office settings.

- Flake and nugget ice machines: Used for food display, healthcare, and beverages, offering softer ice types.

Each machine has unique parts and needs. Our technicians know how to handle these differences to get your system back to work quickly.

Whether you have a rental or a permanent install, we can help.

Common Repair Issues

Most repairs deal with a few familiar problems that slow down your ice production:

- Ice buildup: Melted water freezing where it shouldn’t, causing jams.

- Water leaks: Broken or clogged supply lines disrupting ice making.

- Compressor failure: The refrigeration system isn’t cooling properly, reducing ice output.

- Electrical faults: Faulty wiring or sensors causing the machine to shut off.

- Dirty condensers: Causing overheating and less efficient cooling.

Regular cleaning and tune-ups help avoid many of these issues. When a problem pops up, quick service minimizes lost ice and business interruptions.

Brands We Repair

You probably use one of the trusted ice machine brands in Memphis. We service:

| Brand | Notes |

|---|---|

| Manitowoc | Popular for flake and cube ice |

| Scotsman | Well-known for reliable machines |

| Hoshizaki | Offers nugget and cube ice |

| Ice-O-Matic | Durable, used in many kitchens |

| Follett | Specialty ice machines |

Our experience with these brands means you get expert care tailored to your equipment. No matter the brand, we treat your ice machine like it’s our own.

Why Prompt Ice Machine Repair Matters for Memphis Businesses

Keeping your commercial ice machine running smoothly is key to maintaining health standards and satisfying customers. Quick repairs help avoid costly downtime and protect your reputation.

Health and Safety Compliance

Your ice machine needs to produce clean, safe ice to meet health regulations. When your machine breaks down or malfunctions, bacteria and mold can build up.

This risks contamination that can make your customers or staff sick. Prompt repair stops these problems before they spread.

It ensures your ice is fresh and pure, which is critical for Memphis restaurants, bars, and healthcare providers. Regular service also helps catch issues early, so your machine stays within local health codes and avoids costly fines.

Impact on Customer Satisfaction

Ice is a small but vital part of your customer experience. Imagine running out of ice during the lunch rush or a busy event.

It disrupts service and can frustrate your guests. Fixing ice machines quickly means you keep drinks cold and food fresh without interruption.

Your customers notice reliable service, which boosts your business’s reputation. Well-maintained equipment runs more efficiently, saving you energy and repair costs over time.

Signs Your Commercial Ice Machine Needs Repair

If your ice machine is not working right, it can hurt your business. You may notice weird sounds, leaks, or changes in how much ice your machine makes.

You might also spot ice that is cloudy or smells odd. These issues are clear signs you need prompt professional repair.

Unusual Noises or Leaks

If your ice machine starts making loud, strange noises, it could mean parts are worn out or stuck. Grinding, buzzing, or hissing sounds are not normal and should be checked soon.

Leaks or water pooling near or under your machine are also warning signs. Leaks can point to broken seals, clogged drains, or damaged water lines.

Left alone, leaks can cause more damage and increase water bills. If you see water where it shouldn’t be, call for service right away.

Ice Production Problems

When your machine makes less ice than usual, or stops entirely, repair is likely needed. Reduced ice can happen because of dirty filters, faulty pumps, or failing compressors.

If your machine struggles to keep up during busy times, it can slow your business down. If you notice low output, don’t wait.

Fast fixes keep your workflow steady and customers happy.

Ice Quality Concerns

Poor ice quality hurts your service. If your ice looks cloudy, smells bad, or sticks together, it means the machine isn’t working correctly.

Cloudy ice often means mineral buildup from hard water or dirty internal parts. Bad smells can come from bacteria growing inside without proper cleaning.

Clumpy ice may mean your machine isn’t cycling water correctly or has damaged parts. Clean, clear ice is what your customers expect.

If your ice quality drops, schedule service to fix the problem and protect your business reputation.

Our Commercial Ice Machine Repair Process

When your ice machine stops working, quick and clear action is key. We focus on pinpointing the problem fast and fixing it with care.

We make sure everything works perfectly before we finish. This helps your business avoid downtime and keeps ice flowing smoothly.

Initial Assessment and Diagnosis

First, we start with a thorough inspection of your ice machine. Our technicians check all parts, from the compressor to the water lines, to find the exact cause of the issue.

We use diagnostic tools and years of experience to spot both obvious and hidden problems. We also talk with you about what you’ve noticed and any previous issues.

This helps us tailor the repair to your machine’s history and your business needs.

Professional Repair Steps

Once we identify the problem, we get to work using genuine parts stocked in our trucks. Common repairs include fixing leaks, replacing worn-out components, and cleaning key systems to improve efficiency.

Our team handles Ice-O-Matic, Scotsman, Manitowoc, and other popular brands. Repairs are done on-site whenever possible to avoid extra downtime.

We follow safety and quality standards to make sure your machine runs well for the long term. If a part isn’t available immediately, we keep you updated with clear timelines.

Testing and Quality Assurance

After the repair, we run tests to confirm your ice machine is back to full operation. This includes checking ice production, water flow, and cooling performance.

We also inspect the machine for leaks or unusual sounds. If any adjustments are needed, we handle them right away before we finish the job.

Preventive Maintenance for Ice Machines

Keeping your ice machine in top shape means regular care that stops small problems before they grow. This involves proper cleaning, timing your maintenance visits right, and swapping out parts when they start to wear down.

Routine Cleaning Procedures

Your ice machine needs cleaning often to run well and make good ice. Start by wiping down the surfaces with a mild detergent.

Remove and clean the ice bin and water reservoir to avoid buildup. Filters are key because they catch impurities that can clog your machine or hurt ice quality.

Clean or change these every few months. Also, check for mineral deposits inside and use a descaling solution recommended by the manufacturer to remove them.

Dirty parts can cause leaks, strange noises, or low ice output. A clean machine uses less energy and lasts longer.

Scheduling Maintenance Visits

Set up professional check-ups twice a year, especially in Memphis where humidity and heat can take a toll. These visits include deep cleaning, checking electrical systems, water lines, and testing machine performance.

A maintenance plan timed to your business schedule helps avoid downtime during busy days. Memphis Ice experts can adjust their visits to fit your needs.

Regular visits help catch small issues early, avoiding costly repairs and keeping your ice supply steady.

Replacing Worn Components

Parts like fans, pumps, and filters wear out over time and affect machine efficiency. Watch for signs like odd noises, leaks, or reduced ice output—they often mean a part needs replacing.

Use quality replacement parts that fit your ice machine brand, like Ice-O-Matic or Manitowoc. Replacing worn components on schedule saves you from bigger problems later.

Your technician can recommend when to swap parts based on use and condition, keeping your machine reliable year-round.

Choosing a Reliable Memphis Repair Company

Finding the right company to repair your commercial ice machine means looking closely at their skills and what past customers say. You want a team that knows the local climate and business needs.

It’s important they have proper credentials and a strong track record of happy clients.

Qualifications and Certifications

When choosing a repair company, check for proper certifications. These show the team is trained to handle different brands and models safely and effectively.

Look for technicians with experience in commercial ice machines and refrigeration systems. A company with years of service in Memphis likely understands the regional challenges your equipment faces.

Ask if they have licenses and if their techs receive ongoing training. This means they stay updated on the latest repair methods and safety rules.

Also, see if the company offers warranties on parts and labor. This gives you confidence that repairs will last.

A reliable company will gladly explain all the details before starting work.

Customer Reviews and Testimonials

Customer feedback tells you a lot about a repair company’s trustworthiness. Read reviews online or ask the company to share testimonials from local businesses like yours.

Pay attention to reports on timely service, clear communication, and quality repairs. Look for stories about businesses that got quick and lasting fixes.

Memphis Ice Machine Company, for example, often gets praise for fast on-site repairs and helpful technicians who explain what’s going on. This reduces your stress and downtime.

Positive testimonials show the company values customer care and takes pride in their work. Trustworthy companies treat you like a partner, making sure your ice machine is ready when you need it.

Costs and Warranty Information

When you invest in commercial ice machine repair, understanding the costs and what warranties cover can help you avoid surprises. Knowing how service pricing works and what guarantees protect your equipment ensures you get fair value and reliable support for your business.

Understanding Service Pricing

Repair costs vary depending on the type of ice machine, the problem’s complexity, and parts needed. You’ll usually pay a diagnostic fee to identify the issue, which often applies toward the final bill if you choose the repair.

Labor fees depend on how long the job takes and the technician’s expertise. Some repairs require specific parts, and prices for these parts can differ based on brand and availability.

Emergency or after-hours service may cost more. Maintenance plans can reduce overall repair expenses by preventing problems early.

These plans include regular check-ups and minor fixes, saving you money over time.

Warranty and Service Guarantees

Most reputable service providers back their work with warranties on repairs and parts. Warranties usually cover defects in materials and faulty repairs for a set period, often 90 days to a year.

If your ice machine is under the manufacturer’s warranty, repairs might be free or discounted. Check if your service provider honors those terms or offers their own guarantees.

Always ask about warranty terms before any repair starts. Clear info on coverage helps you avoid unexpected costs and ensures you’re supported if problems return soon after service.

Contacting Commercial Ice Machine Repair Experts in Memphis

When you need help with your commercial ice machine, contact local experts. Memphis Ice Machine Company provides friendly and reliable service to keep your equipment running smoothly.

You can reach them by phone, email, or through their website for quick responses.

Here’s what happens when you contact them:

- Fast scheduling: Their team responds quickly to get your ice machine working again.

- Local knowledge: They know the Memphis climate and business needs, so service fits your schedule.

- Skilled technicians: Experienced pros handle repairs, installation, and maintenance for all ice machine brands.

You won’t face long wait times or unexpected delays. Their fleet of trucks carries parts and serves businesses across Memphis and the Mid-South.

If you have questions, want to discuss rental options, or need to schedule a repair, their staff can help. Call or send a message, and someone will guide you through the next steps.

Frequently Asked Questions

Knowing how to get help, spot problems, find trusted technicians, and keep up with maintenance helps your commercial ice machine run well. Understanding costs and scheduling regular checks keeps your ice machine working without surprises.

What’s the quickest way to get service for my ice machine that’s stopped working?

Call a local Memphis ice machine service provider with fast response times. Many companies offer emergency repairs to restore your machine quickly.

Can you help me understand why my ice machine isn’t producing ice anymore?

Common causes include water supply issues, electrical problems, or a clogged filter. Sometimes the machine needs a simple cleaning or part replacement.

Are there any reliable technicians who specialize in fixing ice machines in my area?

Yes. Memphis Ice Machine Company has served the Mid-South since 1977 with expert repair and maintenance. They know commercial ice machines and focus on quick, clear solutions.

What maintenance tips can you offer to prevent future issues with my commercial ice machine?

Clean the machine regularly, check water filters, and inspect electrical connections. Follow a professional maintenance schedule to catch problems early.

How often should I schedule professional inspections for my ice machine to keep it running smoothly?

Most businesses should have their ice machines serviced at least twice a year. Heavy-use environments may need more frequent attention.

Could you guide me on the potential costs involved with repairing a commercial ice machine?

Repair costs depend on the problem, parts needed, and labor time. Simple fixes like filter changes cost less.

Compressor or control board repairs are pricier. You can get an estimate from a trusted local service to help you budget.

Recent News

Best Practices for Storing Food Around Ice Bins Safely and Efficiently

Best Practices for Loading and Unloading Walk-In Freezers Made Easy and Efficient

Best Practices for Cleaning Walk-In Cooler Shelving Tips for Maintaining Hygiene and Efficiency

Best Practices for Cleaning and Sanitizing Commercial Ice Equipment to Keep It Safe and Sparkling

Best Maintenance Tips for Bar Refrigeration Systems to Keep Your Drinks Cold and Equipment Running Smoothly

Benefits of Working with Certified Refrigeration Technicians for Reliable and Efficient Cooling Solutions