proudly serving

the mid-south

Bar Refrigeration Repair and Maintenance Essential Tips for Longevity and Efficiency

Keeping your bar refrigeration in good working order is essential to protect your stock and maintain smooth operations. Regular maintenance and timely repairs prevent equipment failure, limit downtime, and ensure your beverages stay at the right temperature. Without proper care, small issues can quickly become costly problems that disrupt service.

At Memphis Ice, we understand how critical reliable refrigeration is to your business. Whether it’s a walk-in cooler or a built-in bar fridge, knowing when to schedule maintenance or call for repairs can save you stress and money. This guide will help you recognize common signs of trouble and explain the best steps to keep your units running efficiently year-round.

Types of Bar Refrigeration Systems

Choosing the right refrigeration system affects your bar’s efficiency, drink quality, and maintenance needs. Different units serve specific functions, such as quick access to popular beverages or longer-term storage of large inventory.

Back Bar Coolers

Back bar coolers are essential for bars needing fast access to chilled beverages during peak hours. These units typically feature glass doors to easily view stocked bottles without opening the cooler, reducing cold air loss.

They come in various sizes, from small units for limited space to larger ones that store a wide range of drinks. Maintaining consistent temperature control is vital, as fluctuating temps can affect beverage quality.

Since they work hard during busy shifts, regular cleaning of condensers and checking door seals helps avoid breakdowns and inefficiencies.

Under-Counter Refrigerators

Under-counter refrigerators fit neatly beneath bar counters, offering convenient cold storage without taking up extra floor space. They are perfect for storing garnishes, mixers, or ingredients you need close by.

Most under-counter models are compact but provide reliable cooling with adjustable thermostat settings. Their solid doors keep temperatures more stable, which is ideal when you don’t need frequent visual checks of contents.

Proper airflow around these units is crucial to prevent overheating. Regular maintenance includes cleaning fans and coils to ensure efficient operation and reduce energy consumption over time.

Walk-In Coolers

Walk-in coolers provide the largest cold storage capacity, commonly used for bulk inventory in busy bars and restaurants. They allow you to store large quantities of beverages, perishables, and extra supplies securely.

Their insulation and refrigeration systems are designed for consistent low temperatures, but this demands scheduled maintenance to prevent costly failures. Regularly inspecting door gaskets, defrost cycles, and refrigerant levels minimizes downtime.

Walk-in cooler repair requires professional service, especially if cooling issues arise. For bars in the Mid-South, relying on Memphis Ice refrigeration experts ensures timely and competent support when you need it.

Wine Coolers

Wine coolers specialize in maintaining precise humidity and temperature conditions suited for wine storage. Unlike general bar coolers, they avoid excessive cold or dryness that can affect wine flavor and cork integrity.

These units often feature vibration reduction to protect delicate wines from agitation during cooling. They vary from countertop models to larger, freestanding bottle coolers.

Consistent temperature and humidity control require periodic maintenance, such as cleaning vents and calibrating thermostats. Proper care preserves your wine collection’s quality, making wine coolers a valuable investment for upscale bars.

For further guidance on selecting the right refrigeration solutions, you can explore bar refrigeration options suited to your operation at Memphis Ice.

Key Components of Bar Refrigeration

Understanding the essential parts of your bar refrigeration system helps you identify problems early and maintain optimal performance. The main components work together to keep your beverages chilled and safe.

Compressor

The compressor is the heart of your bar refrigeration system. It pumps refrigerant through the system, raising its pressure and temperature to move it from the evaporator to the condenser coils. Without a properly functioning compressor, your unit won’t circulate refrigerant effectively, causing poor cooling or complete failure.

Common issues include overheating, strange noises, or the compressor running nonstop. Regular inspection for signs of wear or electrical faults can prevent breakdowns. Since the compressor is a mechanically intensive part, professional maintenance by Memphis Ice can extend its life and keep your system efficient.

Condenser and Condenser Coils

The condenser’s job is to release heat extracted from inside the refrigerator to the outside air. It contains condenser coils where the hot, high-pressure refrigerant cools and condenses into a liquid.

Dirt or debris buildup on these coils reduces heat transfer efficiency, causing your compressor to work harder and increasing energy consumption. Cleaning the condenser coils every three months is essential. Also, ensure the condenser fan is working correctly to maintain airflow over the coils.

Poor condenser performance can lead to warm beverage storage and shorten equipment lifespan.

Evaporator and Evaporator Coils

Inside the refrigerated compartment, the evaporator and its coils absorb heat to cool the air. Refrigerant flowing through the evaporator coils evaporates, pulling heat from the interior and lowering the temperature.

If the evaporator coils get dirty or iced over, cooling efficiency drops sharply. This can cause uneven temperatures or frost buildup inside your bar unit. Regular maintenance includes defrosting or cleaning these coils and confirming that the evaporator fan distributes cool air effectively.

A malfunctioning evaporator directly impacts product quality and energy use.

Expansion Valve and Thermostat

The expansion valve regulates the flow of refrigerant into the evaporator, controlling cooling capacity. It reduces refrigerant pressure, allowing it to absorb more heat inside the evaporator coils.

The thermostat monitors the temperature within your bar refrigeration system and signals when to turn the compressor on or off. If either part fails, you could experience temperature fluctuations or continuous running of the compressor, increasing wear and energy costs.

Accurate thermostat calibration and valve function checks ensure stable temperature control and system efficiency. Routine checks or professional service from Memphis Ice prevent temperature-related product loss.

Common Issues and Troubleshooting

Bar refrigeration units face distinct problems that can interrupt daily operations and affect product quality. Identifying and addressing issues early helps maintain consistent temperatures, avoid costly repairs, and extend equipment life.

Temperature Settings Problems

Incorrect temperature settings often cause beverages or perishables to spoil or freeze. Your refrigerator should maintain a stable range between 34°F and 38°F. Settings outside this range can result from accidental adjustments or thermostat failures.

If drinks taste flat or products lose freshness, check the thermostat immediately. Sometimes, the control knob may be loose or misaligned. Calibration errors are also common in older units and may require professional adjustment.

To correct this, verify the temperature display and test it with a separate thermometer. If the problem persists, the thermostat or control board may need replacement. Regular checks help avoid temperature-related problems that disrupt your service flow.

Refrigerant Leak Detection

Leaks in the refrigerant system reduce cooling efficiency and can cause your bar refrigeration unit to stop cooling altogether. Signs include ice buildup on coils, warm air inside the cabinet, or unusual hissing sounds.

You may notice compressor overworking, which raises energy consumption and wears components faster. A sudden increase in utility costs can also hint at a leak. Refrigerant leaks require immediate attention because they impact system reliability and local environmental regulations.

To detect leaks, observe visible signs like oily residue around the evaporator or use specialized electronic leak detectors. Always call trained technicians for repairs; handling refrigerant without certification risks health and legal issues and may damage your system.

Basic Troubleshooting Steps

Start with simple checks before calling for bar refrigeration repair. First, ensure the unit is plugged in and the circuit breaker has not tripped. Clean condenser coils periodically to prevent dust buildup that hinders airflow.

Inspect door seals for cracks or tears, as gaps cause cold air leak and force the system to work harder. Make sure vents inside the unit are clear to facilitate proper air circulation.

Resetting the system by turning it off for a few minutes may solve minor electronic glitches. Document any error codes displayed and share these with your service provider to speed up repairs.

Electrical Faults and Solutions

Electrical problems can cause intermittent cooling, system failure, or complete shutdown. Common issues include faulty wiring, blown fuses, or compressor motor failure. Power surges during storms may also damage sensitive electronic components.

Start by examining power cords, plugs, and outlets for visible wear or burns. Loose connections behind the unit can cause shorts, so check terminals carefully.

If a fuse or circuit breaker repeatedly trips, this signals deeper electrical faults requiring professional diagnosis. Avoid DIY fixes on complex electrical parts; improper handling might lead to injury or further damage.

Memphis Ice recommends preventative maintenance to identify wiring issues early and ensure safe, reliable operation. Your refrigeration system’s electrical health is key to uninterrupted performance and peace of mind.

For expert assistance with bar refrigeration repair and troubleshooting, you can rely on Memphis Ice’s decades of experience serving the Mid-South region.

Preventive Maintenance for Bar Refrigeration

Keeping your bar refrigeration in good condition requires attention to routine tasks that protect efficiency, reduce energy costs, and ensure food safety. Planning and consistent care prevent costly breakdowns and maintain optimal performance for your equipment.

Maintenance Schedule Planning

Start by establishing a clear maintenance schedule tailored to your bar’s refrigeration needs. Ideally, inspections should occur at least quarterly, with some checks monthly—especially during peak seasons.

Regular tasks include checking thermometers, inspecting door seals, and verifying correct temperature settings between 35°F and 38°F for food safety. Document each visit to track trends and spot emerging issues early.

Memphis Ice recommends integrating this schedule with your overall bar maintenance plan to minimize disruptions. Consistency in checks avoids emergency service calls and helps you budget for replacements or upgrades.

Cleaning Condenser and Evaporator Coils

Dirty coils reduce cooling efficiency by forcing compressors to work harder, increasing energy use and wear. Clean both condenser and evaporator coils every 3 to 6 months.

Use a soft brush or vacuum to remove dust from condenser coils located near the compressor. Evaporator coils inside the refrigeration compartment require gentle cleaning to avoid damage and maintain airflow.

Regular coil cleaning can cut energy costs significantly. It also extends the life of your bar refrigeration unit by preventing overheating and compressor failure, key concerns for any business relying on cold storage.

Energy-Saving Practices

Energy efficiency cuts operating costs and lowers your environmental footprint. Simple steps like ensuring door seals are airtight prevent cold air from escaping.

Keep your refrigeration units away from heat sources such as ovens or direct sunlight. Adjust temperature settings slightly higher during slower business hours without compromising safety.

Consider installing LED interior lighting and use timers or sensors on lights and fans to save power. These energy-saving practices support your bottom line while maintaining consistent cooling performance.

Ensuring Food Safety

Maintaining proper temperature and cleanliness directly impacts food safety. Your refrigeration should stay consistently between 35°F and 38°F to slow bacterial growth.

Regularly check for frost buildup or pooling water, which signal potential issues. Clean interior surfaces with food-safe solutions to prevent mold or contamination.

Use a digital thermometer and alarm systems to alert you if temperatures drift outside safe ranges. Memphis Ice stresses that preventive maintenance keeps your refrigeration reliable, protecting both your products and your customers.

When to Call for Professional Repair

Knowing the right time to call a professional helps you avoid costly downtime and ensures your bar refrigeration stays reliable. Key factors include recognizing urgent repair needs, understanding your warranties and service agreements, and weighing repair against replacement options.

Emergency Repair Indicators

Immediate action is required if your bar cooler stops cooling, leaks water, or makes unusual loud noises. These signs often indicate compressor or refrigerant system failure, which can cause product spoilage quickly.

Other emergencies include visible electrical issues like sparks or tripped breakers. Avoid DIY fixes here to prevent further damage or safety hazards.

If you notice excessive frost buildup or temperature fluctuations despite routine adjustments, it’s time to call a technician. Prompt professional help minimizes downtime and keeps your business running smoothly.

Warranties and Service Agreements

Check the status of your bar refrigeration’s warranty before calling for repairs, as some issues might be covered fully or partially. Knowing warranty details helps avoid unnecessary expenses.

Service agreements often include scheduled maintenance and discounted repairs, which can extend your unit’s lifespan and efficiency. Neglecting these can lead to bigger problems down the line.

Review your agreement carefully to understand what services Memphis Ice provides and how quickly they respond within your covered area. This ensures you get prioritized support when needed.

Replacement vs. Repair Decisions

Deciding between repair and replacement depends on your unit’s age, repair cost, and current efficiency. Generally, if your bar cooler is over 10 years old and requires expensive repairs, replacement might be more cost-effective.

Consider energy savings with newer models, as older units often consume more power. However, minor repairs or part replacements can extend the life of a reliable unit significantly.

A Memphis Ice expert can assess your system and help you balance upfront costs against long-term benefits, guiding your decision with local expertise and practical advice.

Additional Bar Refrigeration Equipment

Your bar’s cooling needs extend beyond standard refrigerators and coolers. Ice production and specialty equipment play critical roles in maintaining drink quality and overall service efficiency. Proper care and maintenance for these units ensure consistent performance and prevent costly interruptions.

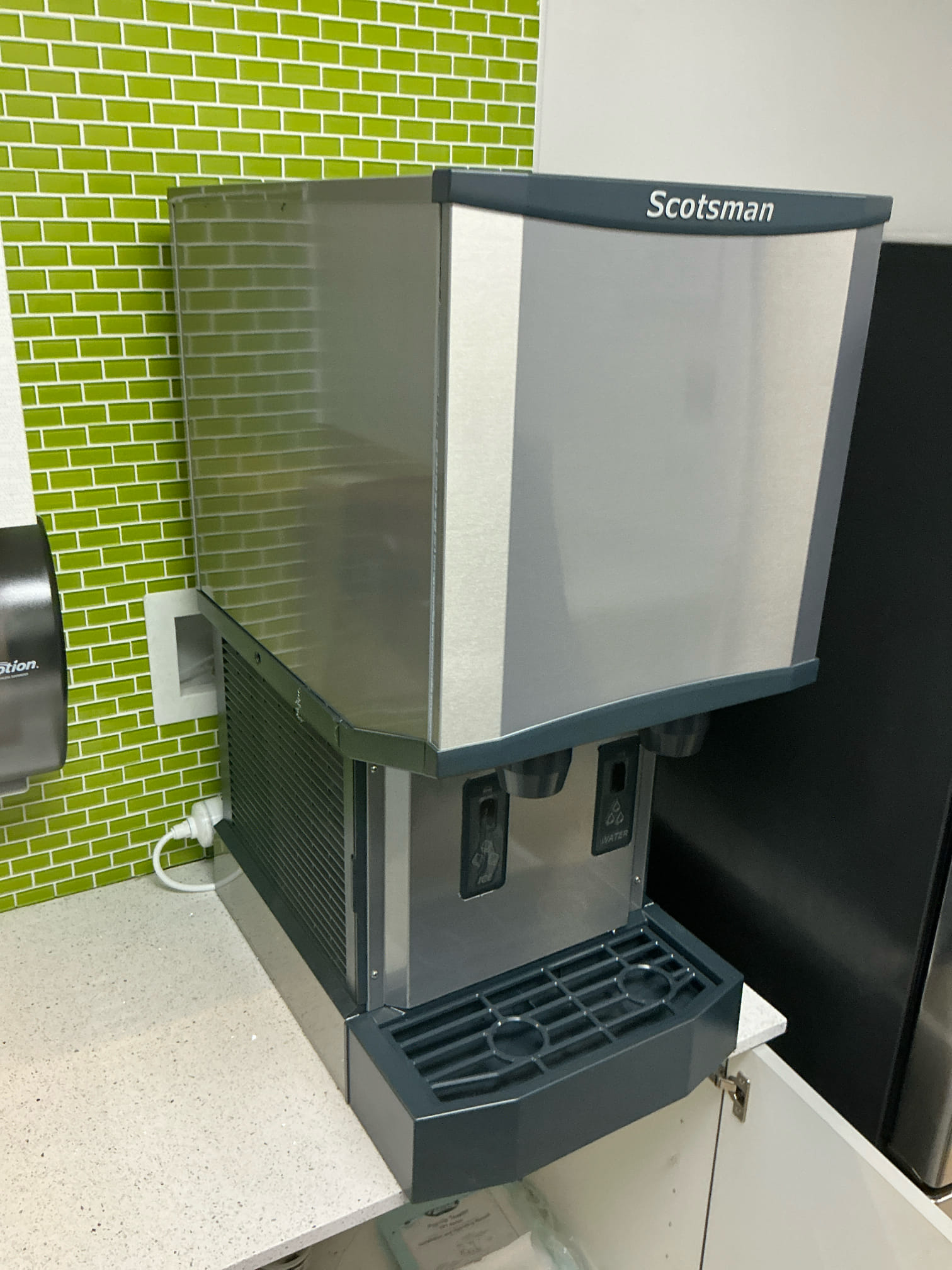

Ice Makers

An efficient ice maker is indispensable in any busy bar. These machines produce large volumes of ice quickly, supporting high customer demand during peak hours. Regular maintenance includes cleaning ice storage bins, checking water filters, and inspecting condensers to avoid slow ice production or cloudy, poor-quality ice.

Preventative care reduces breakdowns that can halt your operations. You should schedule cleaning every few months to remove scale buildup and sanitize parts exposed to water. Memphis Ice recommends professional maintenance to keep your commercial ice machine running reliably through the hottest months. Monitoring operational temperatures and water quality also protects your equipment from wear.

Specialty Bar Equipment Overview

Bars often rely on refrigeration units tailored for specific tasks, such as wine coolers, chilled draft towers, or under-counter refrigeration for garnishes and mixers. Each equipment type requires targeted service to maintain precise temperatures and avoid moisture-related damage.

For example, wine coolers need stable humidity and temperature control to preserve flavor profiles, while ice bins require defrost cycles without interrupting service. Specialty equipment often runs continuously, so timely repairs and regular inspections help extend lifespan and keep your bar running smoothly. Consider having a qualified technician inspect seals, fans, and thermostats regularly. Memphis Ice’s commercial refrigeration service can support these needs with expertise honed over decades in the Mid-South.

Frequently Asked Questions

Knowing the warning signs of trouble can help you avoid costly downtime. Understanding maintenance expectations and how to find skilled professionals ensures your refrigeration runs smoothly and reliably.

What are the common signs that indicate a commercial refrigeration unit needs repair?

You may notice inconsistent temperatures or warm spots inside your unit. Excessive noise, frost buildup on coils, or frequent cycling on and off are also clear indicators.

Leaks around the unit or a sudden increase in energy bills can signal mechanical issues. These signs mean you should schedule an inspection promptly.

How can I find a reliable repair service for commercial refrigeration systems near me?

Look for companies with a proven track record in your region. Experienced technicians who offer clear communication and prompt responses are key.

Ask if they provide service plans and emergency support. Memphis Ice has supported many local businesses with dependable refrigeration service throughout the Mid-South.

What should I expect in terms of maintenance for commercial walk-in refrigerators?

Routine checks should include cleaning condenser coils, inspecting door seals, and verifying temperature settings. Ensure refrigerant levels are monitored, and electrical components are tested for proper function.

Typically, maintenance happens every 3 to 6 months to keep your unit running efficiently and avoid unexpected repairs.

Are there emergency services available for restaurant refrigeration breakdowns?

Yes, many providers offer 24/7 emergency repair services to minimize downtime. Quick response and on-site fixes are vital in food service environments to protect perishables.

Memphis Ice offers reliable emergency support across West Tennessee, North Mississippi, and nearby areas.

How often should commercial refrigeration systems be serviced to avoid major repairs?

Scheduling professional maintenance at least twice a year is recommended. Higher-use units may require quarterly visits depending on load and environment.

Regular inspections identify small issues before they lead to costly failures.

What qualifications should a refrigeration repair technician have for working on commercial equipment?

Technicians should be certified in commercial refrigeration repair and knowledgeable about various system types. Experience with walk-in coolers, ice machines, and bar refrigeration is important.

Verify that they follow safety protocols and use manufacturer-recommended parts to ensure quality repairs.

Recent News

Tips for Improving Airflow Around Commercial Refrigeration Units to Boost Efficiency and Longevity

Tips for Organizing Multi-Zone Walk-In Coolers Made Easy and Efficient

Tips for Organizing Walk-In Coolers for Faster Kitchen Workflow and Efficiency

Tips for Organizing Your Walk-In Freezer for Safety and Efficiency Made Easy and Practical

Tips for Preparing Cold Storage Before Major Events Friendly Guide to Staying Organized and Efficient

Tips for Reducing Odor Inside Ice Machines Easily and Effectively