proudly serving

the mid-south

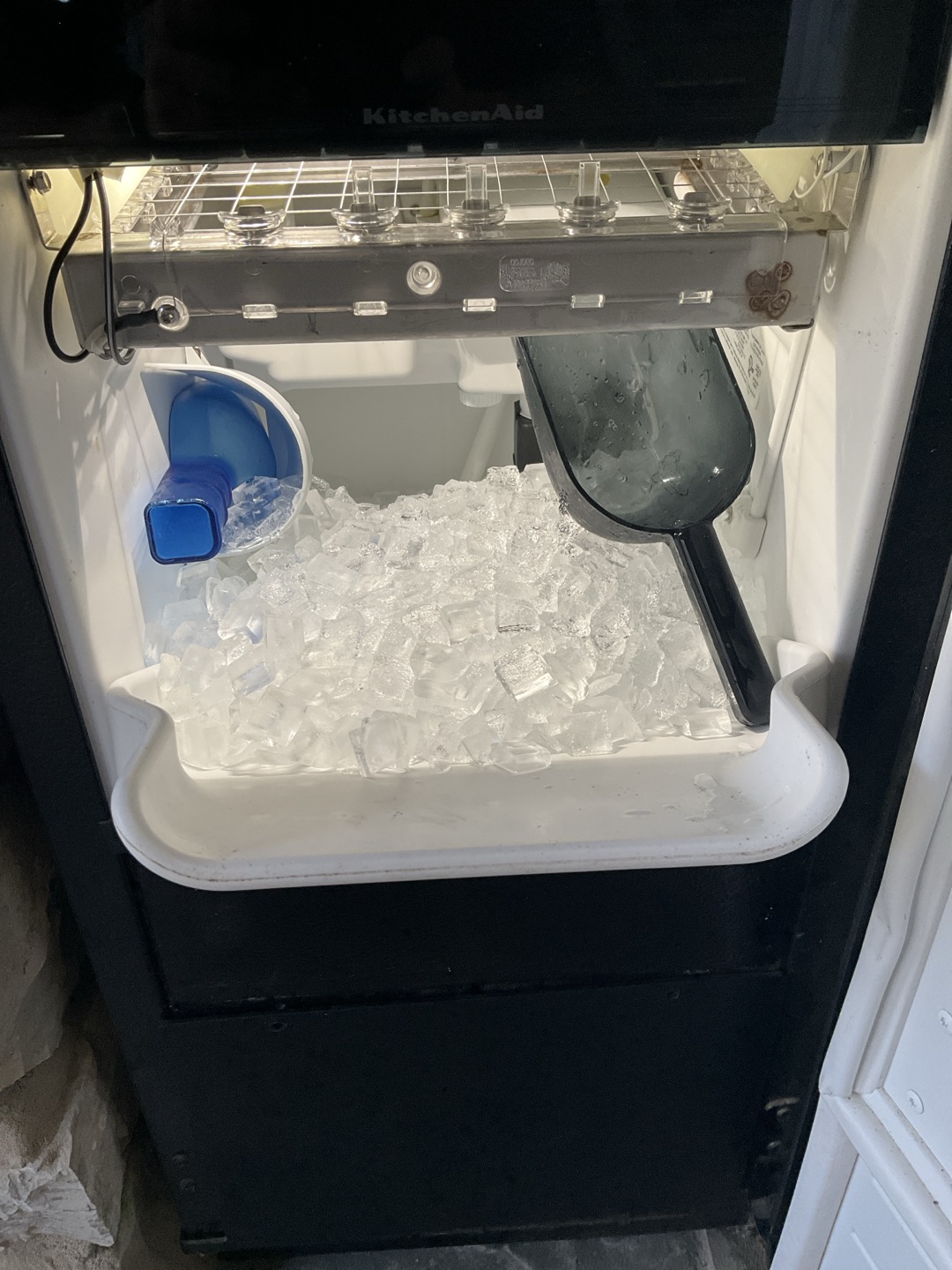

Emergency Ice Machine Repair Services for Fast, Reliable Solutions

When your ice machine breaks down unexpectedly, it can disrupt your entire operation—from restaurant kitchens to hospital service lines. Emergency ice machine repair services are designed to get your equipment back up and running quickly, minimizing downtime and avoiding costly interruptions. Knowing who to call and what to expect can save you both time and stress when every minute matters.

At Memphis Ice, we understand that keeping your ice supply steady is critical, especially during peak demand seasons. With nearly five decades of experience serving the Mid-South, we offer fast, reliable emergency repairs tailored to your specific commercial ice machine needs. You can trust that our team will handle the problem efficiently so you can focus on running your business smoothly.

Understanding Emergency Ice Machine Repair Services

Knowing when an ice machine issue becomes urgent can save time and prevent costly downtime. Rapid repair keeps your business operating smoothly, especially during peak demand or critical service hours.

What Qualifies as an Ice Machine Emergency

An emergency occurs when your ice machine fails and directly disrupts business operations. Examples include complete machine breakdowns, water supply failures, or severe ice production interruptions that leave you without enough ice for service.

Minor issues like slow ice production or noisy operation may not be emergencies but still need attention to avoid escalation. Emergencies require immediate response because ice availability affects food safety, drink preparation, and customer satisfaction.

If your business depends on steady ice output—whether a bar, restaurant, healthcare facility, or grocery store—any halt in production demands quick action. This is why emergency ice machine repair focuses on fast diagnosis and immediate fixes to minimize losses.

Impacts of Downtime on Businesses

Downtime can cause lost sales, unhappy customers, and operational challenges. Without ice, restaurants and bars can’t serve chilled drinks or keep perishables fresh. Hospitals risk compromising patient care when ice-dependent treatments or storage fail.

A mere day without ice often leads to costly waste and rescheduling. For example, retail businesses may spoil refrigerated products or leave shelves empty. Staffing can be disrupted as employees scramble to work around the problem.

The ripple effect of an ice machine outage affects revenue and reputation alike. Minimizing downtime with emergency ice machine repair helps you avoid these consequences and keeps your business running under control.

Importance of Rapid Response

Speed is critical in emergency ice machine repair. The faster a qualified technician arrives, the sooner ice production resumes—limiting business disruption. Immediate service reduces downtime and prevents secondary damage to the equipment.

Rapid response includes quick problem identification, on-site repairs, or temporary solutions such as ice machine rental during extended fixes. Memphis Ice understands this urgency and offers local emergency service to the Mid-South area.

Having access to reliable, prompt repair ensures you won’t be left waiting when ice is most needed. This timely support is essential to maintaining smooth daily operations no matter your industry or season.

For peace of mind and fast resolution, trust experts who prioritize emergency ice machine repair and efficient service schedules. Memphis Ice has been supporting businesses like yours since 1977, keeping your ice and refrigeration needs covered.

Learn more about dependable emergency ice machine repair services to protect your business by visiting an expert resource for commercial ice machine maintenance and repair.

Common Problems Requiring Ice Machine Repair

Commercial ice machines often face issues that disrupt your business operations and ice supply. Prompt repair services help reduce downtime, avoid more costly damage, and keep your equipment running efficiently. Understanding what commonly goes wrong can prepare you to address problems quickly.

Ice Production Failure

If your ice machine stops making ice, the cause is often related to water supply issues or mechanical failures. A clogged water line, faulty water inlet valve, or broken thermostat can interrupt ice production. Sometimes, mineral buildup inside the machine restricts water flow or cooling efficiency.

For commercial ice machine repair, professional technicians will inspect and clean water filters, test electrical components, and verify thermostat function. Timely repair prevents loss of ice, which is crucial in busy settings like restaurants or hospitals. Memphis Ice has been helping Mid-South businesses avoid these disruptions since 1977.

Water Leaks and Freezing Issues

Leaking water or ice build-up inside your machine signals problems with seals, drain lines, or internal components. Damaged door gaskets, cracked drain hoses, or frozen condensate lines can cause leaks or ice overflow.

In some cases, low refrigerant or malfunctioning defrost controls lead to freezing inside the machine, stopping normal operation. Addressing leaks early prevents water damage and maintains hygiene standards.

A licensed repair service will replace faulty parts, ensure proper drainage, and verify refrigeration cycles work correctly, protecting your investment.

Unusual Noises and Performance Drops

Strange sounds, like grinding or rattling, often indicate motor or compressor issues. Worn bearings, loose parts, or failing fans reduce ice machine efficiency and risk complete breakdown.

You might also notice slower ice production and poor ice quality as machines age or components wear out. Regular maintenance reduces these problems, but when noise or performance drops suddenly, professional commercial ice machine repair is essential.

Memphis Ice technicians diagnose the source quickly, recommending repairs or replacements to restore proper function with minimal downtime.

Specialized Commercial Ice Machine Repair Solutions

When your commercial ice machine fails, the right repair approach depends on the type of equipment, its brand, and the scale of your operation. Proper handling ensures minimal downtime and extends the life of your ice maker. The following details help you understand what to expect from specialized repair services.

Repair for Different Types of Ice Machines

Commercial ice machines come in various forms like cubers, flakers, and nugget machines, each requiring different repair techniques. Cubers produce clear, solid ice, flakers make soft, thin ice for immediate use, and nugget machines create chewable ice favored in healthcare and hospitality.

Repairing these machines involves diagnosing issues such as freezing failures, water leaks, or mechanical breakdowns. Your technician will use specialized tools for each type, ensuring the parts specific to your machine are inspected and repaired. At Memphis Ice, we handle all types with efficiency, preventing further damage by addressing common problems like clogged filters or faulty compressors quickly.

Brand Expertise in Commercial Repairs

Different manufacturers design ice machines with varying internal components and software controls. This makes brand-specific knowledge essential for effective repair and maintenance. Technicians experienced with brands like Hoshizaki, Scotsman, and Manitowoc can troubleshoot electrical modules, sensors, and refrigeration cycles accurately.

When you work with Memphis Ice, you gain access to technicians trained on major commercial ice machine brands. This expertise reduces guesswork and avoids unnecessary replacement parts, saving you time and money. Familiarity with brand-specific warranty protocols is also helpful, ensuring repairs comply with manufacturer standards.

Handling Large-Scale and Industrial Equipment

Large-scale commercial ice machines powering hospitals, hotels, or industrial kitchens have higher output and more complex systems. Handling these requires advanced diagnostic equipment and strategic scheduling to minimize disruption.

Repairing industrial units often involves coordinating compressor replacements, managing refrigeration coolants, and ensuring proper airflow in ventilation systems. Your service provider should offer flexible options, including emergency service outside business hours. Memphis Ice understands these demands and provides tailored solutions to keep such critical equipment running peak performance across the Mid-South.

Ice Machine Service and Maintenance for Reliability

Keeping your commercial ice machine running smoothly depends on regular attention that covers inspections, cleaning, and planned upkeep. Proper service and maintenance reduce breakdown risks and help avoid costly emergency repairs, ensuring your equipment stays reliable when you need it most.

Routine Inspections

Regular inspections identify small issues before they escalate into bigger problems. During routine checks, technicians examine key components like the compressor, water lines, and electrical connections to ensure they operate correctly.

You should expect thorough testing of ice production cycles and monitoring for leaks or unusual noises. Inspections often include evaluating sensors and control boards to prevent malfunctions. By catching wear early, you avoid unexpected downtime. For businesses depending on consistent ice supply, these routine checks are an essential part of ice machine service.

Cleaning and Sanitization

Ice machines accumulate mineral deposits, mold, and bacteria, which affect both machine performance and ice quality. A disciplined cleaning schedule removes these deposits and health hazards, maintaining safe, clear ice output.

Cleaning involves disassembling visible parts, scrubbing buildup, and sanitizing water reservoirs and ice bins. Using approved cleaning agents keeps components safe without damage. Failure to properly clean the machine can lead to flavor contamination and reduced efficiency, which impact customer satisfaction. Memphis Ice recommends setting cleaning intervals aligned with your machine’s usage intensity.

Preventive Maintenance Plans

Preventive maintenance plans offer ongoing care tailored to your specific equipment and usage patterns. These plans combine inspections, cleaning, and part replacements to extend machine life and reduce emergency calls.

Typical services include filter changes, lubrication of moving parts, and testing system pressures. You receive scheduled visits from knowledgeable technicians who track your ice machine’s condition over time, adjusting care as needed. Investing in a preventive plan translates to fewer service interruptions, lower repair costs, and better ice quality year-round. Memphis Ice provides customizable maintenance packages designed for Mid-South businesses that count on reliable ice production.

Selecting a Reliable Emergency Ice Machine Repair Provider

Choosing the right emergency ice machine repair service means focusing on specific qualities to ensure fast, effective, and trustworthy support. You need a provider with proven expertise, prompt availability, and clear pricing to avoid surprises during urgent situations.

Expertise and Certifications

You want technicians who have hands-on experience with a wide range of commercial ice machines, including complex models commonly used in restaurants and healthcare facilities. Certifications from manufacturers or industry organizations show they meet professional standards and stay up to date with the latest repair techniques.

Look for companies like Memphis Ice, which bring decades of experience paired with ongoing training to handle emergency ice machine repair efficiently. Skilled technicians reduce downtime by diagnosing issues quickly and fixing them right the first time. This can save you money and prevent further operational interruptions.

Availability and Response Time

When your ice machine fails unexpectedly, every minute counts. Choose a repair provider that offers 24/7 emergency service and guarantees a rapid response. You should be able to contact them anytime and expect a technician onsite swiftly, especially during high-demand periods like summer.

Service providers who prioritize quick scheduling and same-day repairs help avoid disruptions that can impact your business revenue and customer satisfaction. Memphis Ice covers a broad service area in the Mid-South, ensuring local clients get timely assistance without long waits.

Transparent Pricing and Warranty

Clear communication about repair costs upfront helps you plan your budget without stress. Reputable emergency ice machine repair companies provide transparent estimates, outlining parts, labor, and any additional fees before work begins.

Additionally, reliable providers back their repairs with warranties on both parts and workmanship. This commitment gives you confidence that the fixes will last and that you won’t face unexpected charges later. Always ask about these guarantees to avoid surprises and ensure consistent ice machine performance after the repair.

Frequently Asked Questions

Knowing how to recognize issues quickly, find trusted help, and understand costs can prevent downtime and keep your business running smoothly. You’ll want clear expectations about service speed and what machines qualify for emergency repair.

What are common signs that an ice machine needs emergency repair?

If your ice production suddenly slows or stops, that’s a clear warning.

Leaks, unusual noises, or ice that looks misshapen or full of air bubbles also signal problems.

How do I find a reliable emergency repair service for my ice machine?

Look for a provider with verified experience on your specific brand and type of commercial ice machine.

Check for technicians available around the clock to handle urgent needs promptly.

What is the typical response time for emergency ice machine repairs?

Response times vary, but skilled local companies often respond within a few hours.

Rapid diagnosis and service are crucial to minimize disruptions, especially during busy operations.

How much should I expect to pay for emergency repairs on an ice machine?

Costs depend on the issue’s complexity and the parts needed.

Emergency service rates tend to be higher than scheduled maintenance but should be transparent upfront.

Can all types of ice machines be fixed by emergency repair services?

Most commercial ice machines can be repaired if parts are available.

Older or discontinued models may require more time to source components or consider replacement options.

Who should I contact for urgent repairs on a commercial ice machine?

You want a company that offers 24/7 emergency support and extensive service expertise in your region.

At Memphis Ice, we’ve been keeping businesses cool since 1977, providing reliable emergency and routine ice machine repairs throughout the Mid-South.

Recent News

Best Maintenance Tips for Bar Refrigeration Systems to Keep Your Drinks Cold and Equipment Running Smoothly

Benefits of Working with Certified Refrigeration Technicians for Reliable and Efficient Cooling Solutions

Walk-In Freezer Organization Tips for a Cleaner, More Efficient Space

What Impacts Ice Machine Performance In Humid Climates Friendly Tips To Keep It Running Smoothly

Benefits of Routine Walk-In Cooler Maintenance for Restaurants to Save Money and Improve Efficiency

Ringing in the New Year: The Best Drinks Start with the Best Ice